German and American researchers have developed temperature-controlled 'triple-shaped plastics'

Temperature-controlled 'triple-shaped plastics' that can change shape from one form to another, then yet another, have been developed by researchers in Germany and the US.1 Such materials might find use as switches and actuators in microelectromechanical systems (MEMS) and in medicine as intelligent stents for opening up blocked blood vessels.

Scientists at the GKSS Research Centre of Biomaterial Development in Teltow, near Berlin, and the Massachusetts Institute of Technology (MIT) in Cambridge, US, created these new materials by blending two distinct polymers composed of long, chain-like molecules and adding bonds at varying points between them. These cross-links control the permanent shape of the new material at the molecular level. Like in a rubber band, the polymer network can be deformed but then snaps back to its original shape once you let go. A rubber band is composed of a single-shape polymer.

In a dual-shape polymer, the hypothetical dual-shape rubber band can be deformed, and the polymer chains are stretched and twisted. But, if it is cooled below a critical temperature in this new shape, different cross-links form that lock it into this particular shape. When it returns to its original temperature, it does not snap back.

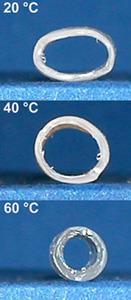

In the novel triple-shape polymers, there is a second critical temperature below which a third shape can be 'locked in'. This is because there are two different polymers cross-linked to each other that respond to two different temperatures by forming different types of cross-links at each temperature. This means each polymer chain in the mix can alter the overall shape of the material. The first change comes at one temperature and the second at another.

Shape-memory polymers, including dual-shape materials, have been around for a while. However, this is the first triple-shape polymer that can change from shape A, to shape B, and then to shape C. The new materials are made from MACL, which contains poly(epsilon-caprolactone) (PCL) segments and poly(cyclohexyl-methacrylate) (PCHMA) segments.

This triple-shape behaviour opens up the possibility of countless technological applications. The first of many might lie in medicine. 'An intelligent stent could be introduced into a blood vessel in a small compact geometry', explains the head of biomaterials at GKSS, Andreas Lendlein, who is working with Robert Langer's team at MIT on the project. 'It could then be inflated at the implantation site to a full-size medical device', he says. 'On demand the device could be removed by shrinking the stent to an easy to handle size, using temperature control'.

Another application might lie in assembly technology. Here, anchor units for fixing a device could be deployed in the first shape-shift step and then locked into a precise position with a second production step. The shape-shifting process is only reversible with a change in temperature, which means it remains intact. 'This is a new principle in materials', explains Langer, 'and it will be producing new opportunities. I imagine that if you had things you want to install, and then remove, the ability to change their shapes at will could be useful'.

David Bradley (sciencebase.com)

References

- A. Lendlein et al, Proc. Natl. Acad. Sci., 2006,103 (48), 18043.

No comments yet