Show students a new recycling method that turns waste into useful chemicals

Download this

A starter slide to use with your 14–16 students and provide a new context for their study of recycling and ways to reduce the use of resources: rsc.li/2Hr4q2c

A one-pot method for converting polyethylenes into more valuable chemicals at low temperature has been demonstrated by researchers in the US. The early-stage research could potentially help tackle the Earth’s ever-growing mountain of waste plastic and offers an alternative route to chemicals currently produced via energy-intensive processes that consume fossil fuels.

The stability and chemical inertness of polyethylene means it does not decompose when disposed of in landfill. Current recycling methods involve washing the polymers before melting them down and reshaping them. However, these recycled plastics have inferior properties and are of lower value than virgin plastics. Alternatively, chemical recycling methods can convert polyethylene back to the monomer ethylene, but this process is highly endothermic, meaning it is not economic.

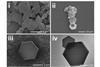

The US researchers converted polyethylenes to long chain alkylaromatic chemicals, which are more valuable than the original plastic. Alkylaromatic chemicals have uses ranging from surfactants and lubricants to refrigerants and insulating oils. The new process uses a platinum catalyst at a relatively low temperature of 280°C. Currently, alkylaromatic chemicals are made in a complicated process using high temperatures.

Read the full story in Chemistry World.

Put this in context

Add context and highlight diverse careers with our short career videos showing how chemistry is making a difference and let your learners be inspired by chemists like Zubera, a research fellow in battery recycling.

Downloads

Upcycling plastic waste starter slide

PowerPoint, Size 0.2 mbUpcycling plastic waste starter slide

PDF, Size 65.58 kb

No comments yet