Crystallisation tool could help meet global lithium demand and string together a greener future

-

Download this

Use this story and the accompanying summary slide for a real-world context when studying crystallisation and separation techniques with your 14–16 learners.

Download the story as MS Word or PDF and the summary slide as MS PowerPoint or PDF.

US researchers have developed a technique that uses an array of strings to significantly speed up the evaporation of lithium salts from brine. This greener approach could help meet growing global demand for the metal, which is needed for electric vehicle batteries and grid storage, as the world moves towards electrification and zero-carbon energy.

The most common way to mine lithium is to pump up brine from underground aquifers to form vast pools on the surface. Millions of litres of water are then left to evaporate for up to 18 months to produce lithium salts. However, such operations are known to contaminate groundwater and harm ecosystems and indigenous communities.

Jason Ren’s group at Princeton University, has devised a rapid crystallisation technique to harvest lithium from both brine and seawater by dangling an array of specially designed strings into the liquids. This approach takes around 20 days, which is nearly 30 times faster than the traditional evaporation method. ‘The process [also] saves a lot of water compared to traditional evaporation approaches,’ says Jason.

A string of successes

The strings are engineered cellulose fibres specially designed in Jason’s lab for this purpose. The fibre cores are water loving, while their surfaces are water repellent. The team spin the fibres into a tight thread before twisting four of the threads together to create the strings.

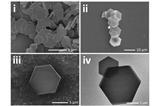

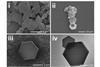

When the strings are dipped in lithium-containing salt water, the liquid moves up them through capillary action – in the same way as plants suck water up from their roots to their leaves. When the water evaporates from the strings’ surfaces, lithium and sodium ions are left behind. As the evaporation process continues, the salts concentrate to form sodium chloride and lithium chloride crystals.

Importantly, the crystallisation of the sodium and lithium salts occurs at separate points on the strings due to their different solubilities, meaning lithium chloride can be harvested easily without additional processes. The team created a 100-string array showing how the concept can be scaled up.

‘Our process is like putting an evaporation pond on a string, allowing us to obtain lithium harvests with a significantly reduced spatial footprint and with more precise control of the process,’ says Sean Zheng, who is leading the launch of a startup, PureLi, to develop this technology.

‘Using this low-cost and chemical-free approach can easily increase the productivity of current brine lakes by many-folds and potentially quench our thirst for lithium,’ comments Shihong Lin, an environmental engineer at Vanderbilt University, who was not involved in the research.

Put this in context

Learn about the role of PhD researcher Lizzie who investigates new materials for lithium-ion batteries.

This article is adapted from James Urquhart’s in Chemistry World.

Nina Notman

Reference X Chen et al, Nat. Water, 2023, 1, 808 (DOI: 10.1038/s44221-023-00131-3)

Download this

Summary slide with questions and the article for context when teaching your 14–16 classes on crystallisation and separation techniques: rsc.li/46zAB6h

Downloads

EiC summary slide Lithium extraction with strings

Presentation | PDF, Size 0.18 mbEiC summary slide Lithium extraction with strings

Presentation | PowerPoint, Size 0.28 mbEiC science research story Lithium extraction with strings

Handout | PDF, Size 0.17 mbEiC science research story Lithium extraction with strings

Handout | Word, Size 0.48 mb

No comments yet