ISIS acts as a super-sensitive microscope. Researchers working at the cutting edge of science use neutrons to find out where atoms are inside materials and what they are doing

-

ISIS provides research facilities for scientists working across a range of disciplines

-

Protons are accelerated to 84% of the speed of light to produce muons and neutrons for experiments

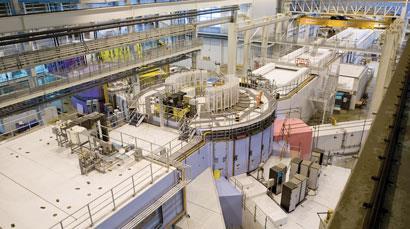

The ISIS pulsed neutron and muon source is one of the principal research centres operated by the STFC (Science and Technology Facilities Council) at the RAL (Rutherford Appleton Laboratory).1 Every year 2000 scientists from 30 countries descend on this corner of the Oxfordshire countryside to perform hundreds of experiments on ISIS across all the sciences, including physics, chemistry, materials engineering, earth sciences, biology and archaeology, though some of the most fruitful work blurs the boundaries between the disciplines.

With the scientific community's apparent obsession with acronyms, it might surprise some that ISIS, is named after Isis, the Ancient Egyptian goddess, who could resurrect the dead. ISIS is aptly named as equipment from Nimrod and Nina, previous accelerators at the site, were cannibalised for its construction. Isis was also the matron of nature and magic. Given that some of the ground-breaking science undertaken at ISIS would not look out of place in a science fiction thriller, we will find out how ISIS works and demystify some of the research that takes place here.

Opened in 1985, pioneering work has included discovering the structure of high-temperature superconductors, and the solid phase of buckminsterfullerene (buckyballs).

ISIS - the basic principle

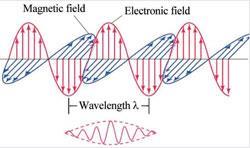

ISIS acts as an extremely sensitive microscope. Using ISIS instruments, scientists can work out where atoms are and measure the forces between them. Neutrons possess a wave-particle duality and have a de Broglie wavelength that allows them to be diffracted by matter in much the same way that x-rays are diffracted by a lattice in x-ray crystallography (see box). But while x-rays interact with the electron cloud, neutrons are uncharged, so they can penetrate deep into matter and interact directly with the nuclei without experiencing electrostatic repulsion.

Louis de Broglie and wave particle duality

Christiaan Huygens believed that light was carried as waves while Newton thought it was composed of 'corpuscles'. Following the insights developed by Fresnel and Young (famous for his double-slit interference experiment), it looked as if waves would win the day. But one of Einstein's famous 1905 papers showed that the photoelectric effect could only be explained by treating light as 'particles' of energy, now known as photons. Einstein showed that light has a wave-particle duality: it can behave either as a wave or particles, depending on the circumstances.

In 1924, Louis de Broglie combined the equations for the energy and momentum of a photon:

![]()

with the wave equation: c = f λ

to arrive at an equation that implies particles could behave as waves, with an associated wavelength:

![]()

where h is the Planck constant 6.63 x 10-34 Js, m is the mass of the particle (neutrons in this case) and v is their speed.

Asked at his PhD viva if his idea could be tested, he suggested firing electrons at a crystal. Sure enough, the electrons were diffracted by the crystal lattice, confirming that particles can also behave as waves. George Thompson shared the 1937 Nobel prize for confirming that electrons are waves, 31 years after his father, JJ Thompson, had proved that electrons are particles.

Inelastic scattering results in changes to the kinetic energy of the diffracted neutrons, which reveals the dynamic behaviour of parts of a sample.

ISIS - the practice

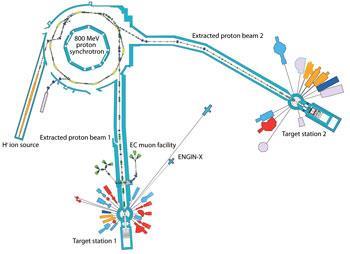

Looking at a diagram of ISIS (fig 1), you can see that it starts with an ion source. This produces negative hydrogen ions, with two electrons orbiting each proton. These are passed into a linear accelerator where, incredibly, they are accelerated to about 35 per cent of the speed of light over a distance of about 50 metres. From here, stripped of their electrons to become protons, they are injected into the circular synchrotron. Its 163-metre circumference is composed of 10 sections, each consisting of an electric field to accelerate bunches of protons and magnetic fields to steer and collimate the pulsed beam. The strength of the bending magnets has to be increased in synchronicity with the increasing speed of the protons, to keep them in the same tight trajectory. After 10 000 trips around the synchrotron, the protons are travelling at 84 per cent of the speed of light. They can then be extracted using three fast kicker magnets in which the current rises from zero to 6500 amps in less than 100 nanoseconds.

Passing through a thin graphite target, two to three per cent of the proton beam produces muons (heavy electrons) for use in muon spin spectrometry. The remaining protons strike a tantalum-clad tungsten spallation target, where each proton can eject about 20 neutrons. The target is water-cooled to prevent the 160 kW proton beam melting it. The neutrons are then slowed down or moderated to increase their de Broglie wavelength before they are channelled through guides, or beamlines, to about 20 instruments, individually optimised for the study of different types of matter. A separate beamline takes protons to the ISIS second target station. Optimised for low energy neutrons, this provides greater capacity at ISIS and opens up new areas of research.

Cella Energy

Cella Energy2 is the first spin-out company from ISIS. Along with colleagues at the London Centre for Nanotechnology at University College London and the University of Oxford, the ISIS team have already won prestigious awards for an innovation that may significantly reduce our carbon footprint and increase our energy security. Cella Energy won the 2011 Shell Springboard Award 'for an invention which brings zero-emission hydrogen cars a step closer'. It also scooped the Consumer Benefit award at the Energy Innovation Awards 2011.

Transport is estimated to contribute about 25 per cent of global man made carbon emissions.

'In some senses hydrogen is the perfect fuel; it has three times more energy than petrol per unit of weight, and when it burns it produces nothing but water,' said Stephen Bennington, Chief Scientific Officer at Cella Energy and the leader of the team behind the innovation that allows ordinary internal combustion engines to burn hydrogen. The hydrogen is pumped into a vehicle like petrol, side-stepping the need to pressurise or liquefy the gas. Up until now, hydrogen storage required a pressure of 700 bar or a temperature of minus 253°C. Inherently risky, both these solutions require considerable energy, as well as expensive infrastructure, including pumping equipment.

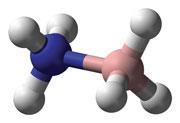

The ultimate goal is electric vehicles driven by hydrogen fuel cells but these are a long way short of commercial viability. The innovation from Cella Energy, which is based on the hydride ammonia borane (fig 2), offers the potential to bridge the gap.

One constraint is the target, set in 2009 by the Department of Energy (DoE), that hydrogen be stored to at least 6 wt% (ie 6 per cent hydrogen by weight) as this is the best that can be achieved by compressing hydrogen to 700 bar. After all, the thick walls that gas cylinders need in order to withstand this pressure contribute the lion's share of the weight. However, complex hydrides such as ammonia borane can store hydrogen at up to 19.6 wt%. Cella Energy is working on speeding up desorption (ie release) of hydrogen at lower temperatures but at the cost of reducing the percentage of hydrogen that can be stored.

Ammonia borane beads

Hydrides soak up hydrogen like a sponge. Cella Energy has manufactured hydride ammonia borane NH3BH3 as micro-fibres, thirty times thinner than a human hair. The result looks like tissue paper (fig 3).3 The material can also be manufactured as micro-beads, which can be poured or pumped like a liquid. Low-cost coaxial electrospinning or electrospraying coats the hydride inside a nano-porous polystyrene. By trapping the hydride in this way, desorption of the hydrogen is faster, can be achieved at a lower temperature and acts as a barrier against contamination. It also protects the hydrides from water and oxygen, so it could be handled in air - even on a garage forecourt.

The ability to pump the beads like a liquid is the key behind overcoming the '3 minute, 300 mile rule', where motorists expect a three minute refuel to last three hundred miles. Electric cars currently fail this test spectacularly with hours of recharging providing a range of only 100 miles. Stephen Bennington's vision is that when you go and refuel your car, you have two nozzles. One which puts in the new beads and one which takes out the old beads which go off to be recycled and the hydrogen added to it again.

Welding unweldable materials

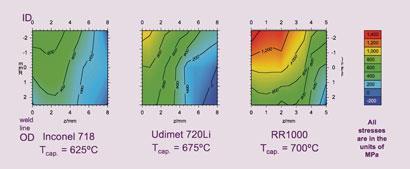

Neutron diffraction using ISIS is helping aerospace engineers perfect welding techniques for high-performance alloys.4 For example, nickel-based 'superalloys' are used in aero-engines because they maintain their considerable strength at high operating temperatures, but they are extremely difficult to join using conventional fusion-welding techniques. Friction welding is preferred. One component, spinning on a flywheel, is brought into contact with a second component, generating enough heat to soften though not melt the weld region. However, this approach risks introducing residual stresses, which can weaken the joint, with the potential for component failure.

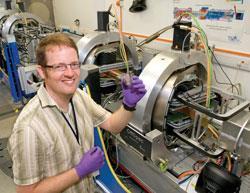

Fortunately, neutron diffraction provides the perfect tool for mapping residual stress (fig 4). Any elastic deformation alters the distances between atomic planes in the material's crystal lattice. This acts as a built-in atomic strain gauge, with the strain inferred from the diffraction pattern. Michael Preuss and colleagues at the University of Manchester, in collaboration with Rolls Royce, have been mapping the stresses in a number of welds using the ISIS instrument ENGIN and its successor ENGIN-X (fig 5). The instrumentation is specifically designed for engineering applications and can even accommodate full-sized components. The research showed that, even when the same process was used, the stress levels depend on the alloy under investigation. The work also helped identify the most suitable post-weld heat treatment and the optimum spin speed for friction stir-welding.

Orthopaedic implants

The same 'atomic strain gauge' approach can also be used to improve orthopaedic implants.5 Early orthopaedic implants often failed because of poor osteo-integration (ie bonding between the implant and the bone). Coating a metal implant with a material that mimics human bone reduced the rate of rejection. Hydroxyapatite (HA) mineral accounts for about half of bone so metal implants coated in this have a better chance of success. However, failure can still occur due to the residual stress developed at the metal-HA interface. Neutrons permit the non-destructive analysis of this interface.

'Clingfilm' solar cells

Scientists from the Universities of Sheffield and Cambridge used the ISIS neutron source and the Diamond Light Source at STFC Rutherford Appleton Laboratory to carry out the research into plastic (polymer) solar cells.6

'Over the next fifty years society is going to need to supply the growing energy demands of the world's population without using fossil fuels, and the only renewable energy source that can do this is the Sun', said Richard Jones of the University of Sheffield. 'In a couple of hours enough energy from sunlight falls on the Earth to satisfy the energy needs of the Earth for a whole year, but we need to be able to harness this on a much bigger scale than we can do now. Cheap and efficient polymer solar cells that can cover huge areas could help move us into a new age of renewable energy.'

Photovoltaics are semiconductor devices that convert solar energy into electrical energy. Until now manufactured from silicon, they can also be made from plastic (so-called organic photovoltaic devices). It is claimed that mass-produced polymer solar cells spread 'like varnish' over large areas could be providing power in years to come. Plastic films only 60 nanometres thick, over a thousand times thinner than a human hair, can be deposited from solution by low-cost roll-to-roll printing techniques similar to the way newspapers are printed and taken off a roll at the end. Apparently fortuitously, when complex mixtures of molecules in solution are spread onto a surface, the molecules separate to the top and bottom of the layer in a way that maximises the efficiency of the resulting solar cell.

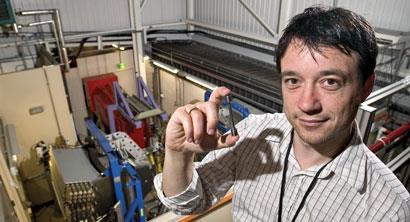

Robert Dalgliesh (right), one of the ISIS scientists involved has said, 'This work clearly illustrates the importance of the combined use of neutron and x-ray scattering sources such as ISIS and Diamond in solving modern challenges for society. Using neutron beams at ISIS and Diamond's bright x-rays, we were able to probe the internal structure and properties of the solar cell materials non-destructively. By studying the layers in the materials which convert sunlight into electricity, we are learning how different processing steps change the overall efficiency and affect the overall polymer solar cell performance.'

Surely his sentiments are echoed by the 2000 scientists who come to use the facilities here every year.

Related Link

Diamond Light Source: illuminating chemistry

Synchrotron light allows chemists to see within structures and individual atoms, without disrupting samples

Resources

ISIS website

Information and resources on ISIS

Inside the ISIS linear particle accelerator

Video and description

Backstage science: Muons

Video and description

Backstage Science: Engin-X

Video and description

Accelerate this: a tour around the synchrotron

Audio and description

References

- www.isis.stfc.ac.uk

- www.cellaenergy.com

- Z Kurban et al, J. Phys. Chem. C, 2010, 114, 21201 (DOI: 10.1021/jp107871v)

- M Preuss et al, Mater. Sci. Eng. A, 2006, 437, 38 (DOI: 10.1016/j.msea.2006.04.058)

- R Ahmed et al, Mater. Sci. Forum, 2010, 652, 309 (DOI: 10.4028/www.scientific.net/MSF.652.309)

- P A Staniec et al, Adv. Energy Mater., 2011, 1, 499 (DOI: 10.1002/aenm.201100144)

No comments yet