A new way to make graphene transforms the traditional sticky-tape method into something scalable

-

Download this

Use this story and the accompanying summary slide for a real-world context when studying carbon allotropes and graphene with your 14–16 learners.

Download the story as MS Word or PDF and the summary slide as MS PowerPoint or PDF.

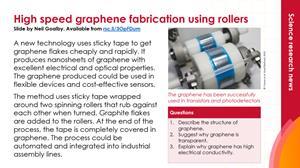

Chemists in Spain have developed a new method for producing graphene flakes cheaply and rapidly. The process may accelerate the commercial uptake of graphene because of its easy integration into industrial assembly lines.

In 2010, the Nobel prize in physics was awarded to Andre Geim and Kostya Novoselov, from the University of Manchester, for their discovery that flakes composed of a single layer of carbon atoms (graphene) can be peeled off from graphite using sticky tape. Since then, a number of processes for producing graphene at scale have been developed.

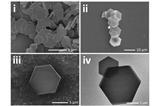

The significance of the new method, developed by Andrés Castellanos Gómez’s team at the Institute of Materials Science of Madrid, is its low-cost, fast speed and the size of the flakes produced. The large flakes it makes are particularly useful for simple transistors and photodetectors suitable for flexible devices and cost-effective sensors. Another advantage of this manufacturing approach over other methods is that it does not require any liquids. This matters because if graphene isn’t completely dry before use, its conductivity may be affected.

A sticky innovation

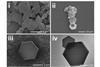

Andrés uses the same tool as the Nobel prize winners – sticky tape. He wraps the tape around two rollers that are positioned so that they rub against each other when turned. Graphite flakes are then placed on a section of the tape, before the rollers are rotated until the tape is uniformly coated with graphene.

The current set-up produces 10 cm2 of graphene at a time. Andrés says the method can be easily scaled up to produce industrially useful amounts of graphene by using larger rollers and wider sticky tape. Andrés and his team have also used the same method to produce other 2D materials, including molybdenum disulfide and boron nitride.

Put this in context

Learn about the role of a patent attorney who helps inventors get legal protection for their new inventions and medicines.

This article is adapted from Fernando Gomollón-Bel’s in Chemistry World.

The large flakes it makes are particularly useful for simple transistors and photodetectors suitable for flexible devices and cost-effective sensors

Nina Notman

Reference

Y Sozen et al, Small Meth., 2023, 2300326, DOI: 10.1002/smtd.202300326

Download this

Summary slide with questions and the article for context when teaching your 14–16 classes on types of carbon: rsc.li/3OSxIY6

Downloads

EiC science research story Making graphene

Handout | PDF, Size 0.18 mbEiC science research story Making graphene

Handout | Word, Size 0.72 mbEiC summary slide Producing graphene

Presentation | PDF, Size 0.22 mbEiC summary slide Producing graphene

Presentation | PowerPoint, Size 0.37 mb

No comments yet