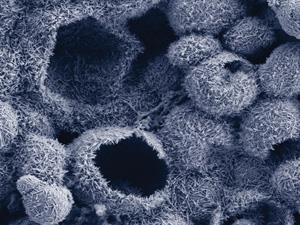

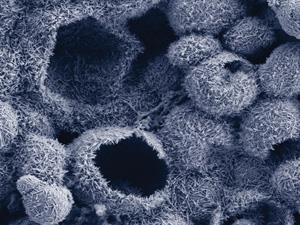

Aluminium-based coating could protect metal components from heat, oxidation

Hollow oxide can take the heat was first published by Chemistry World.

Aluminium-based coating could protect metal components from heat, oxidation

Hollow oxide can take the heat was first published by Chemistry World.

No comments yet