-

- Salary range: £25–40k

- Minimum qualifications: Degree-level qualifications (including master’s)

Studied at: Durham University - Skills required: Strong organisational and communication skills, people-management skills, problem-solving skills, project management skills, mathematical skills, data analysis.

- Training required: Training on how to use on-site equipment.

- Career progression: There may be the opportunity to progress to a senior role such as Head of Department.

- Work-life balance: Senior roles might require working overtime. There may be the opportunity to work flexible hours.

- Locations: Find related work experience positions using our map of employers

More profiles like Paul's

British Sugar manufactures sugar from home-grown UK sugar beet. On this journey, there are a number of other co-products produced, including bioethanol. Bioethanol is a renewable fuel produced from plant matter through fermentation. It goes into fuel called E10 petrol, which is mixture of petrol and up to 10% renewable ethanol. This blend helps reduce the greenhouse gas emissions from petrol vehicles.

What does a senior science manager do?

I manage the scientific services across the largest Sugar Beet factory in the world, developing and implementating process improvements.

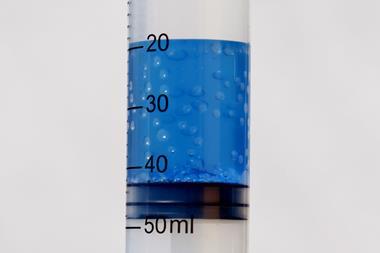

I am lucky because the plant is the biggest chemistry set that I will ever get to play with. My day usually starts with checking in on the team, then I do the same thing with the plant. I look at Key Performance Indicators (KPIs). For Bioethanol, these KPIs are ethanol content and sugar levels to ensure the sugar is being fully consumed by the yeast. If we have any issues with these, we would need to understand why the ethanol content is down, which would involve taking measurements like acetic acid or lactate levels – an indicator that there could be a competing strand of yeast from the environment, which could slightly reduce the ethanol output and might mean we need to disinfect and clean a vessel.

I also work on projects – some lab and some process – to try and improve yield, be it sugar or ethanol, or develop and work with new technologies. For example, we have recently worked with technology partners to develop microscopic counting apps to measure live yeast cells.

How do you go from beet to bioethanol?

The first stage of processing involves cleaning the sugar beets. Tonnes of soil and stones are removed and used for topsoil and aggregate (construction stones). We extract the sugar from the beet using diffusers to give us a raw juice, which is purified and evaporated into a thick juice that is turned into white sugar and molasses within the refinery. The molasses goes on to be separated in a liquid chromatography plant into raffinate (salts), betaine (non-sugars) and extract (sugars). The extract is turned into bioethanol using fermentation.

How is your job helping to make a difference?

I get to see and account for the recovery of all the products on site. Every bit of so-called waste at British Sugar is recovered and reused. Even the carbon dioxide generated during the fermentation process can be recovered in the onsite carbon dioxide liquid plant or supplied to our greenhouses, helping our crops to grow. We take the leftover pulp after we have extracted the sugar and make animal feed from it. Even the water that we get from the sugar beet is recovered, stored and reused to water the next round of sugar beet crops.

How did you get into your job?

I didn’t know what I wanted to do after college – chemistry or geography. I was fortunate that I was steered to chemistry by my parents, who could see that route leading to better job opportunities after university. Following university, I couldn’t get onto a graduate scheme but managed to get a role in a lab and liked it. I then progressed from analyst, to chemist, to supervisor, to manager.

What skills do you need for your job?

I need strong organisational and communication skills – they are quite important when you have a large team. It also helps to have an inquisitive mind and to be able to ask questions. A degree or higher qualification in a science subject is useful – it gives you a baseline of the science that’s occurring. The ability to understand maths and handle data is also useful.

What do you love about your job?

Developing people. I like that I get to build their knowledge with development plans and help them grow their understanding so they get to progress through the company or industry as I do. The best part about that is that you build a culture – a positive one about improvements and opportunities.

Why did you choose chemistry?

I chose chemistry because I had a teacher at school who was brilliant and I remember him doing an experiment one day. He was dropping some group one elements into water and then dropped a bit too much and bolted from his desk in an ‘oops’ moment.

What keeps you motivated?

I enjoy fixing or improving things. I enjoy bringing energy to a task to figure out and eventually understand what happened when a reaction or process didn’t quite go as it should have.

How did your qualification help you get your job?

My qualifications demonstrate my ability to understand science at that level. There are some parts of my qualifications that are useful in some of my roles and some aspects that aren’t used as much. During my qualification, I learned that nothing beats learning while doing: being in a lab, learning to use equipment, getting things wrong, practising and getting better. My advice is that it is OK to make mistakes so long as you learn from them.

What tips or advice would you have for someone looking to get into your field?

Do it! Science is a fun, interesting career. There are always demands for scientists and plenty of avenues you can go down: manufacturing, health and safety, engineering, management, etc. There are also plenty of courses after university – try to do one a year. Continue to expand your CV with courses on quality improvement for manufacturing, project management or occupational health and safety.

Want to know more?

- Explore your study options, talk to a career adviser and look into gaining work experience.

- Learn more aboutE10 petrol.

- Careers at British Sugar

- Browse British Sugar’s website.

Paul Wrathmall, senior science manager at British Sugar.

Published September 2022