A method for growing diamonds in the lab has sparkling potential

-

Download this

Use this story and the accompanying summary slide for a real-world context when studying giant covalent structures with your 14–16 learners.

Download the story as MS Word or PDF and the summary slide as MS PowerPoint or PDF.

Scientists in South Korea have developed a new method for producing synthetic diamonds. The team is now working to optimise the method to grow larger diamonds and diamond films with a range of industrial applications.

Most of the diamonds grown in laboratories are not large gemstones. Instead, they are tiny diamonds, called diamond power or grit, or patchworks of minute crystals that have grown densely packed together, called polycrystalline diamond films or wafers. Among other things, companies use synthetic diamonds to produce extremely hard drill bits and saw blades and as heat spreaders for advanced computer chips.

There are two long-established methods for growing synthetic diamonds. The first uses conditions similar to those in the mantle, where diamonds grow naturally. In a giant press, diamond seeds, graphite (the source of carbon atoms) and a metal catalyst are subjected to extremely high temperatures and pressures. The second method, chemical vapour deposition, uses microwaves to convert methane gas into the carbon atom source for growing diamonds.

Going 3D

The new approach was inspired by previous experiments where researchers rearranged the carbon atoms in methane gas into solid graphene sheets by exposing the methane to molten metal catalysts. The scientists tweaked these experimental conditions to create a different carbon structure: diamond. The carbon atoms in diamonds are in a tetrahedral arrangement with each carbon covalently bonded to four others.

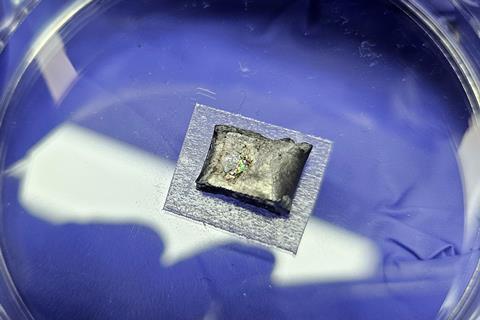

To make diamond, the team exposed a mixture of methane and hydrogen gases to a molten alloy of gallium, silicon, iron and nickel at temperatures of around 1000°C and ambient pressure. They haven’t determined the role of the silicon yet, but without it the carbon atoms do not form diamond’s giant covalent structure.

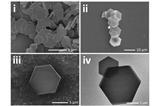

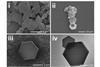

Using this method, the scientists grew polycrystalline diamond films to tens of micrometres across in less than three hours. To make diamond films of useful sizes, they are making further tweaks to the experimental design.

This article is adapted from Tim Wogan’s in Chemistry World.

Nina Notman

References

Y Gong et al, Nature, 2024, 629, 348–354, doi.org/10.1038/s41586-024-07339-7

Download this

A starter slide to use with 14–16-year-old students to provide context for the study of giant covalent structures: rsc.li/3QViaDu

Downloads

Synthetic diamonds summary slide

PDF, Size 0.29 mbSynthetic diamonds summary slide

Presentation | PowerPoint, Size 0.44 mbSynthetic diamonds student sheet

PDF, Size 0.15 mbSynthetic diamonds student sheet

Handout | Word, Size 0.81 mb

No comments yet