Phytomining offers a new approach for recycling single-use plastics using nickel extracted from metal-contaminated soils

-

Download this

Use this story and the accompanying summary slide for a real-world context when studying phytomining with your 14–16 learners.

Download the story as MS Word or PDF and the summary slide as MS PowerPoint or PDF.

Chemists in the UK have transformed nickel extracted from the soil by hyperaccumulator plants into catalysts able to break down difficult-to-recycle low density poly(ethene) (LDPE).

Hyperaccumulator plants are species that thrive in soil with high levels of metal contamination. Metal compounds are absorbed by the plant roots and stored in their tissues. There is growing interest in extracting the metals from these plant tissues and using them in commercial processes.

Recycling of LDPE is an area ripe for innovation. LDPE is one of the most widely used plastics, its uses include plastic bags, wrapping films, bubble wrap and single-use personal protective equipment (PPE). The proportion of LDPE currently recycled is very low, because it is a technically challenging and often not economically feasible process.

Created by nature

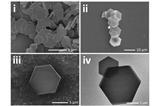

Scientists are starting to explore the use of nickel catalysts to make the chemical recycling of LDPE easier and more affordable. James Clark and his team at the University of York have recently reported that nickel extracted by plants from contaminated soils is particularly suitable for this purpose. The plants take nickel up from the soil in a nanoparticulate form, says James. ‘The nano form of metals is usually really good for catalysis and if you want to make those synthetically it’s really hard work,’ he adds.

James made a catalyst from nickel nanoparticles extracted from alyssum and willow plants that had been grown in soils doped with nickel salts. He then demonstrated that this catalyst could breakdown LDPE into hydrocarbons and hydrogen at around 250°C using microwaves. By tweaking the length of the reaction, the temperature, and the amount of catalyst used, James was able to control the types of hydrocarbons produced.

Nickel remediation

James highlights that an initial goal of the research was to investigate using plants for soil remediation. ‘The motivation for looking at nickel is because there’s a lot of land around the world that’s contaminated with nickel,’ he says. The contamination can be natural, from rocks weathering or volcanoes, or anthropogenic, from traffic fumes or industrial processes such as metal production. Until it is remediated, this land isn’t suitable for growing food.

Next, the team would like to investigate whether the process still works with plants grown on soil contaminated with a mixture of metals. Questions include whether the plants also take up other metals, and if so, whether that matters. ‘Would it matter if [the plants] take up several things? Could you put them through the process and still end up with a viable catalyst?’ James says.

Put this in context

Precious metals can be extracted from electronic waste products using bacteria – a method known as bioleaching. Find out more about the role of a bioleaching lab technician.

This article is adapted from Celeste Brady’s in Chemistry World.

There is growing interest in extracting the metals from these plant tissues and using them in commercial processes

Nina Notman

Reference

P Johar et al, RSC Sustain., 2023, 1, 117 (DOI: 10.1039/d2su00001f)

Download this

Summary slide with questions and the article for context when teaching your 14–16 classes on phytomining: rsc.li/3yqTby1

Downloads

EiC summary slide Phytomining

Presentation | PDF, Size 0.21 mbEiC summary slide Phytomining

Presentation | PowerPoint, Size 2.53 mbEiC science research story Phytomining

Handout | PDF, Size 0.22 mbEiC science research story Phytomining

Handout | Word, Size 0.58 mb

No comments yet