Everything you need to know

-

- Minimum qualifications: Degree-level qualifications (including master’s)

Undergraduate degree studied at: De Montfort University - Skills required: Creativity and critical thinking skills

- Training required: Completing a Diploma in Cosmetic Science

- Work–life balance: Option to travel

- Career progression: Professional registration available, as well as opportunities to apply for more senior positions/responsibility

- Locations: Find related work experience positions using our map of employers

- Find out more: Explore analytical chemist roles in more detail

- Minimum qualifications: Degree-level qualifications (including master’s)

More profiles like Sharlotte's

Barentz is one of the leading life science ingredients distributors in the world. They sell raw materials to companies that make medicines, food, vitamins and personal care products.

What does a technical services chemist do?

I make or formulate sample cosmetic products from Barentz’s raw materials that the sales team can present to customers. These include shampoos, shower gels, lotions or any product relating to hair care or skin care.

If you imagine the raw materials Barentz supplies are eggs and flour, my role is to make them into a delicious cake so that customers can see what the eggs and flour can create. Instead of cakes, I make end cosmetic products that our sales team can then present and share with their customers to promote our raw materials.

How does your work affect the world around us?

As the average person uses between 5–15 personal care products, it is vital for our health that there are no harmful ingredients in cosmetic products. I discover new ways of formulating environmentally friendly, safe cosmetic products adhering to the strict rules and standards of government and regulatory bodies on the manufacturing, labelling and marketing of cosmetic products. My work also seeks to reduce carbon emissions by finding energy-efficient ways to manufacture care products, helping to create a more sustainable UK beauty and personal care market.

What is your typical day like?

Most days, I am developing end cosmetic products. This involves a series of steps:

- I receive a project brief – for example: make a lotion.

- I research the raw materials required to make that particular formulation and the regulatory information.

- I write up a draft formulation – ie a list of ingredients with the quantities for each to make the end product; in this case, a lotion.

- I check I have the materials I need.

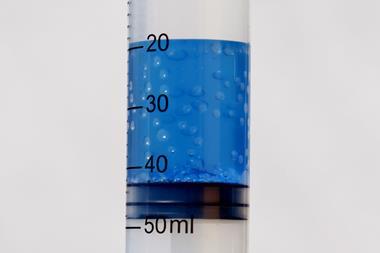

- I get started with formulating that product in the laboratory. That involves measuring out the quantities and preparing them in the required way.

- It is rare that the formulation would come out perfectly the first time, so a few trials would be needed before getting an end sample fit for conducting stability tests on.

My days can also mean travelling to Paris or Amsterdam for training which is great for discovering news.

What do you love about your job?

I have a strong love for the environment, so the best part about my job is that I often get the opportunity to work with and promote a lot of sustainable ingredients and I am allowed to be intensely creative when thinking of new ways of formulating with those materials.

Why did you choose chemistry? What keeps you motivated?

I’ve always been hugely creative and curious about the world around me so, naturally, I gravitated towards science growing up – especially the practical aspect of it.

What keeps me motivated in my job is that I can contribute in the movement towards more environmentally friendly ingredients and production processes within my industry by formulating beauty products with novel textures and formats using upcycled (reused) or sustainable ingredients.

How did you find your job?

In my last year of university, my friend sent me an email our lecturer had sent out advertising a technical services chemist job role. I submitted my CV along with a cover letter for that role, then went through a two-stage interview process. I was successful in both interviews and so, thankfully, got the job!

How did your qualification help you to get your job?

I studied biology, chemistry and health and social care at A-levels and then went on to complete my pharmaceutical and cosmetic science degree at university, which helped me get my foot into the cosmetic industry. I then went on to do a one-year distance-learning Diploma in Cosmetic Science with the Society of Cosmetic Scientists (SCS) while working at Barentz. The course gave me the knowledge and confidence that I needed to guide others in their formulating journey.

What barriers did you encounter on your journey into your role?

I gained a base knowledge of formulating from my university degree. However, when I started working, I realised that I would benefit more from building upon my knowledge. There aren’t many places where you can learn cosmetics so I was grateful that I found and enrolled onto a Diploma in Cosmetic Science.

What tips or advice would you have for someone looking to get into a similar role, or considering a career in your field?

I would recommend attending local tradeshows or getting some work experience in various departments in the cosmetic product development process.

What do you see yourself doing in the future?

I hope to deepen my involvement with supporting customers’ queries, becoming a go-to resource for both customers and fellow colleagues whenever they are in need. I also hope to continue taking part in STEM activities as I’ve found myself in an amazing industry that many aren’t aware of and so feel it’s important that we inform others about the industry and support the younger generation in their future career ventures.

Want to know more?

- Explore your study options, talk to a career adviser and look into gaining work experience.

- Check out the Society of Cosmetic Scientists’ website for more information on science-based careers in the cosmetic industry and the courses they offer.

- Browse the British Beauty Council’s website for events.

- Find out more about qualifications, skills and salaries for cosmetic chemists on Youth Employment UK

- Explore more jobs on Not Just Labcoats

Sharlotte Chamisa RSci, Technical Services Chemist, Barentz

Published May 2024