Scientists propose a more sustainable and less noxious method for metal extraction

Download this

Invite students to look at metal extraction using electrolysis and its level of sustainability as an industrial process using this starter slide.

Download this

Invite students to look at metal extraction using electrolysis and its level of sustainability as an industrial process: rsc.li/XXX

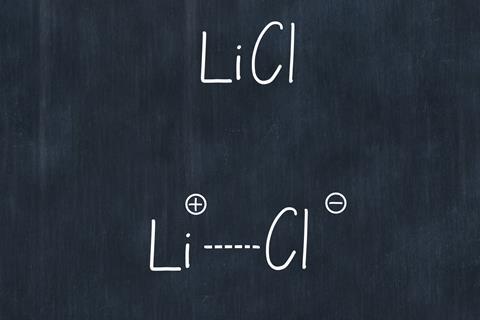

Lithium battery technology is widely seen as essential for the switch from fossil fuels to renewable energy generation. This has led to a massive increase in demand for lithium. The present process for extracting lithium is unsustainable – requiring high temperatures and toxic reagents to purify mineral sources.

Researchers have shown that incorporating a layer of a solid ceramic electrolyte into the electrochemical cell used to extract lithium helps solve several of these problems. Only lithium ions can pass through the ceramic, so the electrolytic cell can use unpurified lithium chloride, saving on the cost and use of toxic reagents.

Put this in context

Add context and highlight diverse careers with our short career videos showing how chemistry is making a difference and let your learners be inspired by chemists like Lizzie, a PhD researcher.

The new process also allows aluminium chloride to be added to the molten salt without risk of aluminium metal being deposited at the cathode. The lower melting point of the lithium and aluminium chloride mixture allows energy to be saved by operating the cell at a lower temperature.

Use the starter slide with your class to help them think about the sustainability of extracting metals using electrolysis.

Read the full story in Chemistry World.

Downloads

EIC starter slide Cheaper lithium extraction

Editable handout | PowerPoint, Size 0.24 mbEIC starter slide Cheaper lithium extraction

Handout | PDF, Size 77.1 kb

No comments yet