Reducing the temperature needed to produce high-quality glassware

Download this

A starter slide to give 14–16-year-old students a new context for comparing the properties of materials and plastics.

Fused silica glass offers numerous benefits as a material, but manufacturers often avoid using it because of the high temperatures required to mould the glass into usable shapes. However, researchers in Germany have now produced high-quality glassware at far lower temperatures using injection moulding. Their technique could potentially have significant technical, economic and environmental benefits.

Silica glass is produced simply by heating grains of silicon dioxide until they melt. It has remarkable chemical stability, optical clarity and durability. In the last century, however, manufacturers have increasingly used polymer-based products, which often have inferior properties and have become notorious environmental contaminants. One reason is that many polymers can easily be shaped by injection moulding – heating the material until it softens before injecting it into a pre-formed mould. This usually occurs at 200–250˚C. By contrast, silica glass melts at around 2000˚C. Aside from the enormous energy demands, there are not many materials for making moulds that can sustain these temperatures.

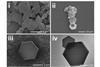

The team of researchers have discovered a new way of carrying out injection-moulding with glass. They used an extremely high concentration of ceramic nanoparticles, solvated in a polymeric binder, producing a fluid that could be injection-moulded into any shape. Some of the binder was then washed out and recovered before the researchers heated the material to 1300˚C. This drove out the remaining binder and caused the nanoparticles to soften and merge. The researchers made measurements which, they claim, showed that scientific quality glass components could be produced without further processing.

Read the full story in Chemistry World.

Put this in context

Add context and highlight diverse careers with our short career videos showing how chemistry is making a difference and let your learners be inspired by chemists like Gemma, a product and process development manager.

Downloads

Injection-moulded glass starter slide

Presentation | PowerPoint, Size 0.18 mbInjection-moulded glass starter slide

Presentation | PDF, Size 0.2 mb

No comments yet