Andrew Turley investigates the history of Pyrex, one of the best known brands in chemistry

When I left for university, my mum insisted I take with me several ‘important’ items that seemed completely unnecessary to me. The clear, Pyrex casserole dish was typical.

‘Just take it with you,’ she said. ‘It’ll come in handy.’

Annoyingly, she was right. That Pyrex dish, which I still have in my kitchen, has ‘come in handy’ fairly frequently over the past 14 years. How did she know that it would? Well, it occurs to me now that the item has a combination of characteristics that set it apart.

First, it’s a mass produced item, which means it should be relatively cheap to replace in the event of breakage. Second, it’s transparent, which means I can see what’s happening at the bottom, regardless of what’s above it. And third, it’s robust, which means I don’t need to worry about how I use it in the kitchen. It is, most obviously, safe to use in the oven.

What is interesting is how little things have changed in the 100 years since the Pyrex brand was launched. Indeed, back in 1915, consumers found Pyrex dishes useful for more or less the same reasons I do now.

Cracking up

The organisation behind Pyrex was Corning Glass Works, a US company based in Corning, New York. A few years previously, in 1908, they had developed ‘non-expansion’ glass, marketed under the brand name Nonex.1 It was designed for use in railway signal lighting, in response to the switch from kerosene lamps to arc lamps. The latter generated much higher temperatures leading to thermal shocks when it was cold or rainy, and the shocks caused the soda lime glass to crack more frequently. A glass better able to handle thermal stress was needed. The solution Corning came up with was borosilicate glass, which didn’t expand to the same extent when heated and consequently cracked far less often.

Indeed, Nonex borosilicate glass for railway lighting had to be replaced so rarely the company was soon looking for new markets in order to maintain profits. As it happened, the company had been considering a move into consumer products for several years. All it needed was a little push in the right direction from a resourceful housewife.2

In 1913, Bessie Littleton was upset that her earthenware casserole dish had cracked after only its second use. She asked her husband Jesse, a Corning physicist, to bring her back from the glassworks something she could use as a substitute. At that time, the company used Nonex glass for battery jars, as well as railway lighting, and Jessie decided that he could make something reasonable by sawing the bottom off one of the jars. The result was remarkably successful: Bessie noted the pleasing uniformity of the sponge cake she baked in it and the ease with which it was removed from the dish. As a result, Jesse Littleton and his colleagues became convinced that cooking and baking could be made more efficient through heat-resistant glass.

Nonex, however, was not safe for food contact use because of the lead content. Fortunately, Littleton was able to alter the composition without affecting the main characteristic of the glass, and the result was a transparent material that was highly resistant to thermal, chemical and mechanical stresses.

Thus, through Pyrex and Nonex before it, Corning found a way to market borosilicate glass to the masses.

But people were using it long before these developments, they just weren’t fully aware of its commercial potential. In fact, the earliest work on borosilicate glass had nothing to do with heat or chemical resistance but was in the field of optics.

An odyssey in optics

In 1876, German physicist Ernst Abbé gave a lecture in London on the subject of glass for optical lenses, in which he criticised the glasses available in Europe.3 Abbé had established a theoretical limit for the resolving power of a lens and found that contrary to conventional wisdom the factor holding back progress was not the physical manipulation of the glass required to form the lenses but rather the quality of the glass in terms of chemical composition. New types of glass were sorely needed, he declared. Fortunately, in the audience that day was Otto Schott, a German chemist from a family of glassmakers. The year before, Schott had gained his doctorate on the theory and practice of glassmaking and was experimenting with composition. He sent some samples to Abbé, who was impressed and invited Schott to move to Jena in Germany to work with him.

In 1884, they established Glastechnisches Laboratorium Schott & Genossen (Schott & Associates Glass Technology Laboratory) with the help of Carl Zeiss, the owner of a local optical workshop. They developed a borosilicate glass they found to be ideal for use in laboratory thermometers owing to its thermal and chemical resistance and launched it in 1893.

Schott and his borosilicate glass helped to cement Germany’s position as the primary source of laboratory glassware at the end of the 19th century. But the outbreak of the first world war interrupted trade, and in the years that followed, Corning expanded its laboratory glassware operations to meet demand in the US.

Raising the profile

Later, the company found a surprising range of applications, outside of the mainstream. In 1934, for example, Corning cast a 200 inch disk of Pyrex for use in the Hale Telescope at the Mount Palomar Observatory in California, US. Pyrex was chosen because of its extremely low coefficient of expansion, which meant the mirror would not distort the images too badly as a result of internal temperature variations, although the original plan had been to use a large, fused quartz block to be manufactured by General Electric.

Initially, the work did not go well. When the 20 tonnes of molten glass was poured into the mould, the intense heat caused several of the moulding blocks to break loose and float to the top, ruining the product. Fortunately, after some modifications to the moulding apparatus, the second attempt proved more successful. The cast layer was then given six months to cool in the annealing process before being transported to Pasadena for shaping and polishing. It took seven and a half years – including an interruption of about five years as a consequence of the war effort – for the optical workshop to carefully grind away the five tonnes of excess glass. After that, the mirror was coated with a reflective aluminium surface using vacuum deposition. The telescope, with the 200 inch mirror, was completed in 1948, at which time it was the largest optical telescope in the world.

Glass’s cutting edge

Pyrex is even associated with a few famous names. Charles Lindbergh is best known today for his 1927 flight across the Atlantic. But in the 1930s, he was helping to invent medical equipment made of Pyrex.4 Specifically, Lindbergh worked with Nobel prize winning surgeon Alexis Carrel on the perfusion pump, an instrument designed to help keep organs alive outside the body. The Pyrex was critical: other materials tested caused blood clots and other complications in the organs.

In addition to products, Pyrex has itself given rise to other innovative materials and driven the development of new technology. The conventional furnaces made of refractory blocks and bricks, for example, had to be redesigned to accommodate the new glass because, at the much higher temperatures needed for borosilicate glass, the melt corroded the insides.

But for chemists, clearly, the most important impact of Pyrex has been on the world of laboratory glassware, where the chemical resistance of borosilicate glass comes to the fore. Indeed, it’s hard to imagine laboratory chemistry without borosilicate glass, such is its significance. It is particularly hard to imagine how Quickfit-type glassware would be possible without the extremely low coefficient of expansion of Pyrex.

How does it work?

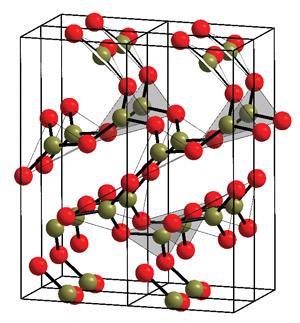

Soda lime is the most common type of glass. It is made from silicon dioxide (silica; sand; SiO2), plus a small amount of sodium carbonate (‘soda’; Na2CO3) and calcium oxide (‘lime’; CaO). The primary difference with borosilicate glass is the use of boric oxide (B2O3), which results in less of the other constituents being needed. In particular, the amount of sodium oxide falls from about 14% in soda lime glass to about 4% in borosilicate glass. This has a dramatic effect on the heat resistance of the glass because of the relatively high coefficient of expansion of sodium oxide compared with similar oxides. It is the expansion of the glass during heating that causes fracturing. It also has a dramatic effect on the chemical resistance because of the relatively high reactivity of the sodium species. Indeed, a glass made exclusively of silicon dioxide and sodium carbonate is actually quite soluble.

That said, the thermal and the chemical resistance of a glass depends on a complex set of factors relating to the manufacture process, as well as the composition. The thickness, for example, is critical to thermal resistance.

Easy to assemble

Although it has become a generic term for all ground glass jointed laboratory glassware, Quickfit, like Pyrex, is a brand name. It came from Quickfit and Quartz Ltd, a UK manufacturer of laboratory equipment and scientific instruments.5 The company was introduced to Pyrex in 1953, when it started working with James A Jobling and Co., the company that owned the rights to Pyrex in Britain and most of its empire. The union was cemented in 1953 when Jobling acquired Quickfit in its entirety and consolidated the laboratory glassware operations in Stone, Staffordshire.

Since then, there has been considerable reorganisation of the companies. In 2008, SciLabware was born, the division that is the exclusive licence holder for Pyrex laboratory glassware in all regions outside the Americas and China. In 2011, the company was bought by the Duran Group, one of the largest manufacturers of borosilicate glass, and in 2013 it moved to Stoke-on-Trent.

The glass SciLabware uses is manufactured in accordance with the ISO 3585 standard for 3.3 grade borosilicate.6 In short, this means that the composition is no secret (see box) and in theory anyone could set themselves up as a competitor.

But in practice, it would difficult.

Firstly, you would need to acquire the equipment and get it up and running. ‘It is massively expensive to enter this market,’ says Andy Davies, sales and marketing manager at SciLabware. ‘You need a tank: imagine a standard front room with a sort of bolt on kitchen on the side – a tank that size that contains about six tonnes of molten glass. And you can’t turn it off for at least four years. It runs all the time.’

Secondly, you would need people who could work the glass properly. It can take seven years for a junior member of the glassblowing team to master the skills, Andy explains. Glassblowing is not a skill many people learn as part of their education, so hiring can be a challenge. Fortunately for the company, Stoke-on-Trent and its surrounding regions are rich in workers with the kinds of dexterous skills that overlap well, thanks to the legacy of the pottery industry. Such people may be more familiar with the manipulation of ceramic cups, jugs and plates than glass piping, but they find it relatively easy to adapt their skills.

Composition of Pyrex borosilicate glass

SiO2: 80.6% B2O3: 13.0%

Na2O: 4.0% Al2O3: 2.3%

‘The composition of the glass is only half the story,’ adds Laura Morrey, glass products manager. ‘The other half is manufacture with uniform thickness, removing the stress from the glass as it cools – all of which ensures the product lasts a long time. You don’t necessarily need to drop it for it to break.’

One of the key steps in the process is annealing, during which the glass is cooled very slowly in a lehr to limit the internal stresses in the glass. It is needed because of the way in which glass contracts as it cools. The outer-most part cools quickly, which generates a rigid skin. This is then pulled in towards the core as the innermost part cools. The faster the glass is cooled, the more uneven the internal stresses.

Lastly, and most importantly, you would need to give the market something new, which in this area would be difficult to do, given the excellent commercial performance of the well established products. Andy says that the top selling product at SciLabware is one of the simplest: the 250 cm3 Pyrex beaker. The rule seems clear: if it isn’t broke, don’t try to fix it.

And if it is broke, buy Pyrex next time.

Andrew Turley is a writer based in Cambridge, UK

References

- B Howard, Am. Biotechnol. Lab., October 2005 (http://bit.ly/1N5rbQC)

- S Stage and V B Vincenti (eds), Rethinking home economics: women and the history of a profession. Cornell University Press: 1997

- Chemistry World, May 2015, p37

- http://bit.ly/1Hylk27

- Pyrex: 60 years of design, Tyne and Wear County Council Museums, 1983

- http://bit.ly/1KB4ZA8

No comments yet