Industrial byproducts of metal alloy manufacturing get a second life as clean hydrogen fuel producers

-

Download this

Use this story and the accompanying summary slide for a real-world context when studying electrolysis and catalysis with your 14–16 learners.

Download the story as MS Word or PDF and the summary slide as MS PowerPoint or PDF.

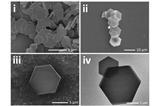

New research shows that filings and shavings left over from grinding, drilling, and cutting metal alloys can be transformed into catalytic electrodes for water splitting. The nanotextured surface of the waste metal is perfect for holding single atoms of platinum and cobalt. These act as electrocatalysts, speeding up key reactions on the electrode’s surface.

Producing hydrogen fuel through splitting water using electrolysis will be important for addressing future global energy demands. However, the environmental impact of mining precious metals to make electrodes is an ongoing issue.

To address this challenge, a team at the University of Nottingham, UK has taken advantage of the nanotextured surfaces of waste pieces of stainless-steel, titanium and nickel alloys. Although the metals appear smooth, the researchers used scanning electron microscopy to discover tiny grooves on their surfaces. These nanoscale grooves can anchor single atoms of platinum and cobalt to produce efficient electrocatalysts.

Importantly, the team found they needed significantly less platinum and cobalt compared to state-of-the-art commercial catalysts.

This research shows how waste metal pieces that are expensive to recycle, or that would otherwise be disposed of, can be repurposed. It also offers a route to using smaller amounts of rare elements in catalysts for water splitting. The researchers are confident their concept will be transferrable to industrial-scale production.

This article is adapted from Kate Tustain’s in Chemistry World.

Nina Notman

References

M Thangamuthu et al, J. Mater. Chem. A, 2024, doi.org/10.1039/d4ta00711e

A starter slide to use with 14–16-year-old students to provide context for studying electrolysis: rsc.li/4dYJGK9

Downloads

Clean fuel from metal waste summary slide

Presentation | PDF, Size 0.22 mbClean fuel from metal waste summary slide

Presentation | PowerPoint, Size 2.34 mbClean fuel from metal waste student sheet

Handout | PDF, Size 0.23 mbClean fuel from metal waste student sheet

Handout | Word, Size 1.1 mb

1 Reader's comment