Biofineries produce heat, power and a plethora of useful 'platform chemicals'. Are they part of the solution to our renewable energy woes? Josh Howgego finds out

The UK currently gleans 9.4% of its energy from renewable sources, but that is not enough. In the next eight years that figure must rise to 15% to conform with European environmental directives. At first sight that might not sound like too big a challenge; the proportion of UK energy generated from renewable sources grew by 2.6% last year, and if it were to continue in that fashion until 2020, 30% of our energy would be renewable.

Unfortunately it's not that simple, according to Adrian Higson, a biobased chemical consultant at NNFCC in York, UK. Most of the recent gains have been due to developments in extracting methane gas from landfill waste, he says. But technologies that extract energy from waste products like sewage, rubbish and waste cooking oil are reaching maturity; they are unlikely to continue providing additional improvements. 'I think meeting that target is going to be potentially quite difficult,' says Higson.

Scotland meanwhile has set itself the target of producing all of its energy from renewable sources. 'That sounds high, but Scotland doesn't use a lot of energy and already has plentiful hydro- and wind energy generation,' says Higson. When it comes to understanding energy, scientific reasoning is important, but geographic, social and political factors also need consideration. Nothing is quite as straightforward as it seems.

Biofuels: part of the solution

Higson believes that increasing our use of biofuels in an intelligent way could be an important aid in meeting these targets. But deciding which types of biotechnology should be part of the picture is a difficult job for policy makers. They must balance the need for a quick fix, driven by political targets, with ensuring the most sustainable technologies are championed.

There are plenty of sustainable fuel technologies being developed, but it's important to have an idea for how close they are to being deployed commercially. But just because a one particular technology is well developed compared to others doesn't mean it should be rolled out across the country. There are other things to consider.

For example, Petrobras, a Brazilian bioethanol company, is the world's biggest ethanol exporter, having made 21 billion litres in 2011. Their bioethanol making process is up and running already, and the ethanol can be mixed with petrol to work in existing automobile engines. But the raw material for Petrobras' industry is sugar cane, a food crop. Some would see this as unethical, since the increased demand for sugar cane (for motoring as well as eating) might drive up sugar prices and hit poorer consumers disproportionately.

But Higson sees arguments about the ethics of biofuels as a distraction, for the most part. 'You need to think about the reasons why people don't eat - and they have very little to do with supply. We have more than enough food in the world to feed everybody comfortably at the moment and that doesn't happen. But biofuels are certainly not the reason for that.'

Matters are also complicated when it comes to the carbon footprint of biofuels. In theory, biofuels would be carbon neutral, the idea being that the carbon they release when burnt is equal to the amount they have extracted from the atmosphere to grow. This is, however, an over-simplification, because processing of the crops, as well as the manufacture of pesticides and herbicides needed to nurture them, all leave a carbon footprint which must be accounted for.

Lignocellulose

Higson says the most important factor in deciding which biofuel strategies are the best is their sustainability. To make biofuels work in the long term we will need lots more biomass, cheaply and quickly. That takes effort - and we need to be sure it is something we can keep up.

'At the moment the agricultural industry is focused on growing crops that we can eat,' says Higson. 'Those crops need a good climate, good soil, and they're generally annual plants. So they take a lot of effort to grow. But if you can use different biomass - that is, not sugar and starch - then you can grow different crops which don't need that quality of land.'

The first generation of biofuels were made from the obviously energy-rich sugars in plants, but now there is a second generation of technologies which have another starting material in their sights: lignocelluloses. While this material makes up the vast majority of all plant matter on earth, our agricultural systems are not yet focused on it. In general, we are not interested in growing plants for the sake of their stems and branches (the lignocellulose-rich parts), but for their fruit and flowers. Higson says the situation necessitates a switch in attitude: to growing crops on the poorest quality (and hence cheapest) land possible, with the least care requirements and the easiest processing needs. This will provide us with lots of economic biomass in a sustainable way.

Second generation energy crops

The attractions of lignocellulose have led to the proliferation of so-called second generation biofuels. Switch grass, and Miscanthus (elephant grass) are both popular energy crops, together with willow and poplar trees. These can be grown on cheap, poor quality soil.

Energy giant BP has chosen to invest in second generation biofuel crops. They are concentrating their efforts on so-called 'energy cane', a modified version of sugar cane which grows taller than regular cane, at up to 18 feet high.

Matt Casswell, US regulatory affairs director at BP biofuels says: 'What separates cellulosic biofuels from traditional biofuels is that cellulosic has more biomass per acre, so it's more productive. It can produce four or five times the amount of fuel as the first generation biofuels [made from sugars] can. And on top of that, because it's a perennial grass - you plant it one time and it grows for 20 years - it has a much higher environmental performance than anything that's occurred up to this point.'

BP use microorganisms to digest the cellulose and spit out ethanol. They have recently built a demonstration plant in Jennings, Louisianna, US, where they are developing biofuel manufacture from 'energy cane' at a commercial scale.

What is lignocellulose?

Lignocellulose is a term used to describe a mixture of the two major chemicals that are used in plant architectures: lignin and cellulose.

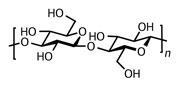

Cellulose is a very long polymer of D-glucose. Chains can be as long as 10 000 monomer units. About 33 percent of all plant matter is cellulose, making it the most common organic molecule on earth.

Lignin is the material used by plants to strengthen their stems and their xylem, the water-transporting tubes which convey liquid from the roots upwards. The chemical structure is a random cross-linked polymer, including many phenolic units. The rigid aromatic rings make the material strong, but also resistant to chemical degradation.

Excess oxygen

Once the problems of sustainability have been conquered, it's time to think about how to convert the raw biomass into a fuel. Most of our current fuel-making chemical infrastructure is designed with crude oil as the feedstock. But lignocellulose is very different to crude oil - it has much more oxygen in it. And according to Higson that is is both a blessing and an inconvenience: 'Fuel chemists would come at lignocellulose saying "oxygen is bad because it just reduces the energy content of the molecule"'. But you can also look at lignocellulose from the point of view of a polymer chemist, looking to make functionalised monomers. Currently such experts must do battle to imbue chemical functionality into the dull hydrocarbons of oil. From that perspective, lignocellulose looks much more appealing. 'You'd be thinking: 'it takes an awful lot of energy and money to place heteroatoms [like oxygen] into hydrocarbons,'' says Higson. 'But with lignocellulose the oxygens are already there, so it's a huge benefit to be working on biomass rather than crude oil.'

Biorefineries: adding value

When biomass is viewed as a feedstock for a variety of useful outputs - not just fuel, but also heat, power, functional chemicals, water and gasses - then the idea of a biorefinery begins to look pretty sensible. But what is a biorefinery? Higson, who specialises in advising on these, explains they are more of a philosophy than a rigidly defined set of rules.

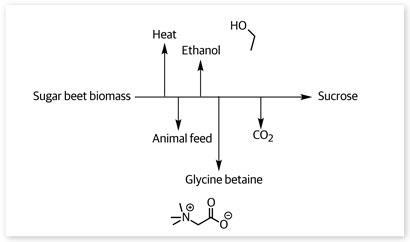

The idea is that a particular biomass feedstock goes in at one end of the process with a target chemical being produced at the other. But useful co-products are siphoned off along the way, with a 'zero-waste mindset'. It's not just materials, but also power that is carefully managed. The endo- and exotherms produced during the chemical reactions are harnessed using heat exchangers, so very little external heating or cooling is needed. An example is the British Sugar refinery in Norfolk, says Higson. It takes in sugar beet and produces sucrose - producing ethanol as a co-product, as well as glycine betaine and carbon dioxide.

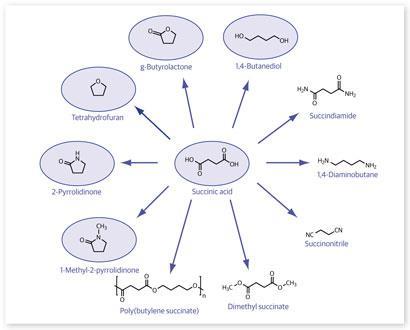

Different biorefineries can produce different product profiles, but Higson explains that succinic acid (SA) might prove to be the most important platform molecule - a molecule which can be used as a springboard from which to make a raft of other useful chemicals - available from biomass. At the moment it is only a relatively niche chemical. Up to 30 000 tonnes are produced globally each year, with each tonne priced at $2-3000. SA is mainly used as a beverage sweetener, but it (and its derivatives) can also be used as platform chemicals for the industrial synthesis of drugs, as solvents, and for making biodegradable polymers.

According to the NNFCC, succinic acid could soon become much more important. Succinic acid is currently made at scale from maleic anhydride in crude oil. This makes it relatively expensive, but if biorefineries could begin producing succinic acid much more cheaply it might suddenly make economic sense to use it in producing other important chemicals.

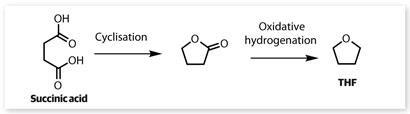

One particularly important chemical which can be made from SA is the solvent and monomer tetrahydrofuran (THF). Until recently, few chemists have studied the transformation of SA to THF because SA is prohibitively expensive. But with bio-SA becoming cheaper, researchers from South Korea have recently shown that it is possible to hydrogenate SA directly to THF using a ReCl5 catalyst impregnated into a porous, solid carbon support which has been pre-treated with H2SO4.1

Training for the future

A revolution in biofuels will soon begin to make many more platform molecules available cheaply, and chemists have an important job in ensuring that industry can make the best use of these in producing the molecules we need for society. It will also be the role of chemists to work out the best ways to analyse and separate the complex broth of products that biorefineries produce, says Higson.

Although developing new catalysts and reactions for derivitising platform molecules is essential, the chemists of the future must know more than simply how to do reactions. They must also understand the basics of engineering and biotechnology.

Higson says it has always been the case that industrial chemists needed to have a decent grounding in engineering, so they could come up with industrial reactions that weren't totally impossible for engineers to accommodate. 'But the extra complexity in this new century is that a lot of the processes that we are going to use are based on biotechnology,' says Higson. 'So you need the engineers, the chemists and the biotechnologists to all work together.

'Otherwise It'll be a case of the engineers optimising a process and the chemists showing up and saying, "hang on, I can't isolate the product from that". And then the biologists will say, "well, that's not the product we're going to make anyway."'

So what should we be doing to ensure we have the right people and the right research going on to make biorefineries a reality? Higson says the two key areas are training and pilot projects. Funding providers like the BBSRC and the EPSRC are already recognising the need to train scientists with an awareness of disciplines other than their own. This has resulted in schemes like the Centres for Doctoral Training (CDTs), which, according to the EPSRC, aim to champion both scientific 'breadth and depth' in PhD students. Higson calls these a 'positive step'.

In terms of funding, Higson says we need to step outside of our comfort zone. 'What we often do in the UK is to back our strengths. But you can't have strength in something that's new, by definition. So how do we begin to grow new strengths? I think you have to back emerging sectors that are of strategic interest to the UK.'

The funding bodies do support large, multidisciplinary projects, which give people the chance to come together, says Higson. 'The trouble is, at the moment, the level of funding tends to be too low.' And perhaps - given the targets that UK must reach by 2012 - biofuels should be considered a strategic interest. It's encouraging, says Higson, that the BBSRC named bioenergy a strategic priority in their 2010-2015 plan. Time will tell whether it will be enough to generate the exciting developments the UK needs to meet the 2020 targets.

Josh Howgego is a science writer based in London, UK

Related Link

Organic Synthesis for Sustainable Biofuels

Organic synthesis contribute to the production of biofuels from non-edible carbohydrate feedstocks to increase both the availability of biofuels and the sustainability of the biofu...

Downloads

Full article as it originally appeared in Education in Chemistry

PDF, Size 0.53 mb

References

1. U G Hong et al, App. Cat., A, 2012, 415, 141 (DOI: 10.1016/j.apcata.2011.12.022)

No comments yet