The ‘spontaneous combustion of iron’ as described in Lister’s Classic chemistry demonstrations was one I wanted to try from my first year of teaching but was put off by not having iron(II) ethanedioate in stock. If I had read more closely, I would have seen that the entry described not only the reaction, but also how to generate the starting material from substances far more likely to be found in a school stock cupboard. The result can be an easy, reliable and quick demonstration of the effect of surface area on rates of reaction and properties of materials.

Download the technician notes as MS Word or pdf. An extract from T. Lister’s Classic chemistry demonstrations describing the original demonstration, with kit list and instructions, is also available for download as a pdf.

Preparation of iron(II) ethanedioate

Kit

- 6.7 g sodium ethanedioate (oxalate) (harmful if swallowed and on contact with skin)

- 13.9 g iron(II) sulfate(VI)-7-water (harmful if swallowed, causes skin irritation, causes serious eye irritation)

- 100 cm3 1M sulfuric(VI) acid (causes skin and eye irritation)

- two 500 cm3 beakers

- filter paper and funnel

- sample vial

Preparation

Wear eye protection. Dissolve 6.7 g (approx. 0.05 moles) of sodium ethanedioate in at least 200 cm3 of water. The solubility is 3.7 g/100 cm3 at room temperature so some gentle heating may be required to speed up dissolution – extra water is well tolerated but will require longer to filter.

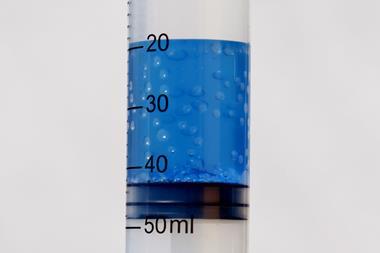

Dissolve 13.9 g (approx. 0.05 moles) of iron(II) sulfate(VI)-7-water in at least 100 cm3 of 1M sulfuric acid (see CLEAPSS recipe RB 051 for guidance). When the two solutions are mixed, a bright yellow precipitate of iron(II) ethanedioate is formed which can be collected by filtration and left overnight to air dry. You will obtain 8–9 g of product, enough for four demonstrations.

Safety note

Carbon monoxide is an extremely flammable gas:

- toxic if inhaled;

- may damage the unborn child;

- causes damage to organs through prolonged or repeated exposure.

It has no taste or smell and can be very difficult to detect. Quantities produced in this demonstration are small but uncertain because of the complexity of the reactions which take place. The decomposition of the iron(II) ethanedioate should be carried out in a ducted fume cupboard. The filters in school re-circulatory fume cupboards do not absorb carbon monoxide. You could use such a cupboard if there is very good room ventilation, since the cupboard would disperse the fumes very rapidly through the room, so the concentration would be below the workplace exposure limit.

Demonstrating the reaction

Kit

- approx. 2 g iron(II) ethanedioate (harmful by ingestion, and in contact with skin)

- borosilicate boiling tube

- Bunsen burner

- mineral wool

- test tube holder

- heat-resistant mat

In front of the class

Wear eye protection and work in a ducted fume cupboard (see safety note below). Place the iron(II) ethanedioate in the boiling tube and loosely plug the end with mineral wool. This allows vapours to escape while preventing the fine powder from spraying out. Heat the end of the tube in a Bunsen flame. The yellow solid will turn black and, as carbon dioxide and carbon monoxide are evolved from the fine grains, may appear to have ‘liquefied’. Droplets of water will condense on the walls of the tube as water of crystallisation is driven off. Once the thermal decomposition is complete, leave the boiling tube on a heat-resistant mat to cool. The pyrophoric nature of the resulting finely-powdered iron can be demonstrated simply by pouring the cooled contents out onto the heat-resistant mat from a height. Dim the lights in the room for the best effect.

Following the reaction, the powder can be inspected to reveal the rusty colour of the resulting iron oxide.

If making up and using the solution immediately, use only a few drops of 1M H2SO4 for instant precipitation. As well as preventing oxidation of the iron(II), the acid inhibits the precipitation, so the solution made up in 1M H2SO4 can take at least one hour to fully precipitate.

Teaching goal

Although aspects of the chemistry here reflect redox reactions in the blast furnace, this experiment is perhaps best suited as a quick demonstration of surface area effects in kinetics. Beforehand you can demonstrate that an iron nail or a paperclip will not react at all when placed in a Bunsen burner, and iron filings, which don’t burn in the air at room temperature, will spark as they oxidise when poured through a Bunsen flame. The iron produced in this reaction appears to react in a different way – demonstrating the great interplay between thermodynamics and kinetics. Just because something is predicted to happen, doesn’t tell us anything about how fast it will happen.

Build a lesson around this demonstration

Try this experiment as part of a lesson plan with activities for 11–14 year olds, using particle models to explore what happens during the combustion of iron – see How are particles rearranged when iron burns in air?.

The hydrated iron(II) ethanedioate exists as a coordination polymer at room temperature with the ethanedioate ion in a bridging configuration between two iron centres, and two water ligands occupying each axial position. Upon initial heating, water of crystallisation is driven off – as evidenced by the droplets that condense further up the tube (Equation 1).

FeC2O4.2H2O → FeC2O4 + 2H2O

Equation 1: release of crystal water (170–230°C)

As the temperature reaches 230°C, carbon is driven off as oxides and magnetite is formed (Equation 2). At 360°C the only products in the solid are superparamagnetic magnetite nanoparticles (Hermanek et al., 2006). Such particles are typically less than 50 nm in size (Román, 2014). Above this temperature, carbon monoxide is able to reduce any remaining iron(II) ethanedioate to iron carbide (Equation 3), again yielding particles at the nanometer scale.

3FeC2O4 → Fe3O4 + 4CO +2CO2

Equation 2: formation of magnetite and evolution of oxides of carbon (230–360°C)

3FeC2O4 + 2CO → Fe3C + 7CO2

Equation 3: reduction by carbon monoxide (> 360°C)

The iron carbide will then thermally decompose above 415°C (Equation 4) and above 535°C the magnetite will reduce to ferrous oxide (Equation 5)

Fe3C → 3Fe + C

Equation 4: thermal decomposition of iron carbide (415–535°C)

Fe3O4 + CO → 3FeO + CO2

Equation 5: reduction of magnetite by carbon monoxide (> 535°C)

Downloads

Technician notes

PDF, Size 36.73 kbTechnician notes

Word, Size 50.85 kbThe spontaneous combustion of iron demonstration (book extract)

Experiment | PDF, Size 32.61 kb

No comments yet