How chemistry keeps firefighters safe on the job

Fire is the effect of a rapid chemical reaction that involves fuel and oxygen reacting to produce carbon dioxide and water. Chemistry also plays a vital role in protecting firefighters from the risks inherent to their career choice, putting out fires and preventing them from starting in the first place.

A firefighter’s personal protective equipment (PPE) is essential to their safety. While on the job, a protective coat, trousers, helmet, gloves, boots and breathing apparatus help protect them against multiple threats. They reduce firefighters’ exposure to extreme heat and harmful chemicals or biological hazards such as blood and sewage.

Two closely related polymers, Nomex and Kevlar, are the main materials used in the protective coats, trousers and gloves worn by firefighters. ‘These are high molecular weight, engineered organic polymers,’ explains Zane Frund, material science lead at MSA Safety, a global manufacturer of safety products including firefighter PPE.

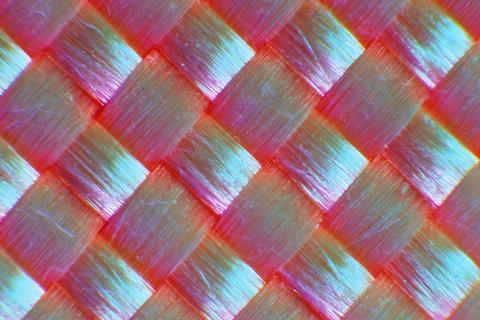

To make firefighter PPE, single polymer filaments are first spun together to make yarn and then woven into a fabric

Polymer protection

Nomex and Kevlar are both brand names coined by the US chemical company DuPont who developed them in the 1960s. In both Nomex and Kevlar, the long chains of the polymer – the backbone – contain aromatic rings connected by amide groups. A key difference between the structures of the two polymers is the position where the amide groups are attached to the aromatic rings.

In your class

Use the chemistry of firefighting to add context to your curriculum topics, from the polymers in the PPE worn by firefighters, to the elements present in the fire retardant chemicals. Discuss the potential hazards associated with the use of fire retardants and use the research into more sustainable alternatives as an example of the development of scientific thinking.

To make the lightweight Nomex and Kevlar fabrics used in firefighter PPE, single polymer filaments are first spun together to make yarn and then woven into a fabric. The inherent stability of the aromatic rings makes Kevlar and Nomex intrinsically fire retardant and extremely durable. These polymers are also thermally resistant, protecting firefighters from extreme heat, and chemically resistant, protecting them from acids, alkalis and hydrocarbon spills. This combination of properties means Nomex and Kevlar are used extensively in protective clothing for roles far beyond firefighting.

While Nomex and Kevlar are very similar, there are some performance differences. Nomex has better thermal resistance; it is able to withstand prolonged exposure to temperatures around 400°C and provide short-term protection from significantly higher temperatures, such as those experienced during a flash fire. Nomex is also more resistant to fuels than Kevlar. It is therefore the fabric of choice for racing car drivers, military pilots, tank drivers and astronaut PPE. Kevlar, meanwhile, is the stronger and more durable of the two. It is used in stab vests and bulletproof vests, as well as cut-proof gloves and military helmets. The two polymers can also be spun together into a combined yarn and used to create a blended fabric.

A layered approach

Firefighter coats and trousers consist of three layers, each with its own function. The primary function of the outer shell is to provide protection from heat. It is composed of Nomex (or a blend of Nomex and Kevlar) and polybenzimidazole. The latter is a thermally stable polymer also used extensively in space suits, heat-protective gloves and protective equipment for welders.

The middle layer is the moisture barrier. ‘Its function is to provide high-level water repellence to the jacket and [trousers], thereby minimising any weight gain from sucked-up water,’ Zane says. This layer is also designed to let water vapour (sweat) travel through it; it is breathable. The middle layer is normally laminated, meaning it’s made up of two or more polymer layers stuck together. One layer is typically Nomex or Kevlar while another is polyurethane or poly(tetrafluoroethylene), better known as Teflon.

The inner core is the thermal liner. This layer is composed of a cotton towelling layer and one or more layers of wadding, each composed of a polymer mixture that includes some Nomex, Kevlar or both.

The overall three-layer approach to PPE design has remained constant in recent years, says Zane. Advances in fabric weaving technology, fabric surface treatments and optimisation of individual layer thicknesses have resulted in garments capable of meeting the ever-increasing and more rigorous firefighter safety standards and user demand for products to be more durable, comfortable and longer lasting. ‘Further improvements are expected as fabric suppliers develop and optimise breakthrough technologies,’ Zane says.

The fire triangle

For a fire to burn, it needs heat, oxygen and fuel. This is called the fire triangle. Removing just one of these three elements will extinguish the flames. For most fires, removing heat is the tool of choice, typically using water.

Water isn’t suitable for every fire type, though, and should never be used on oil or other flammable liquid fires. Putting water on chip pan fires, for example, causes a fireball to form. ‘Water’s heavier than the oil and it’s got a lower boiling point, so it’s going to drop to the bottom of the pan and turn into steam,’ explains Richard Hull, professor of chemistry and fire science at the University of Central Lancashire. As the steam escapes the pan, it sprays droplets of burning oil into the air. Electrical fires should also never be extinguished with water. Since electricity travels through water, using water on electrical fires can result in an electric shock. ‘The danger is the conducting path between the electricity and anything living that touches the runoff water,’ says Richard.

This coloured powder contains compounds that chemically alter the fire to reduce its intensity

Flammable liquid and electrical fires should be put out by removing oxygen from the fire triangle. Small fires of this type can be smothered with a fire blanket or carbon dioxide extinguishers. Fire blankets form a seal around the fire, preventing more oxygen from reaching the flames. Carbon dioxide is denser than oxygen, so it sinks over the flames, displacing the oxygen.

Removing fuel from the fire triangle is the third tool for suppressing fire and is often used to stop wildfires spreading. A fire break is created by cutting down trees or clearing dry leaves, twigs and fallen branches and trees from the forest floor.

-

Download this

Practical activity, for age range 11–14

In this practical, your learners plan and carry out their own investigation into the reagents that produce carbon dioxide foam.

Download the student worksheet as MS Word or pdf. Download the investigation support sheet as MS Word or pdf. Download the teacher notes as MS Word or pdf. Download the technician notes as MS Word or pdf. Download the slides as MS Powerpoint or pdf.

Download this

Practical activity, for age range 11–14

Use this practical activity to get your learners to plan and carry out an investigation into the reagents that produce carbon dioxide foam.

Download the resources from the Education in Chemistry website: rsc.li/3qEBGKv

Fire retardants

A type of chemical called a fire retardant can also reduce heat and the amount of flammable fuel and oxygen available to the fire. Fire retardants come in many different forms. They are used extensively for firefighting and for the treatment of materials as a preventative measure, to reduce the likelihood and severity of fires.

The foams used by firefighters on some large fires contain fire retardants in the form of surfactants. These lower the surface tension of water, which makes it easier to smother the flames. During a large wildfire, fire retardant powder is sometimes dropped from the air around the edges of burning regions to try and contain its spread. This coloured – typically red or orange – powder contains compounds that chemically alter the fire to reduce its intensity. ‘Fire retardants tackle fire [at] the molecular level,’ explains Svetlana Tretsiakova-McNally, an expert in fire retardants from Ulster University. Many everyday plastics and textiles contain, or are coated with, fire retardant chemicals that work the same way.

Shells from eggs and seafood both contain molecules that, if they could be successfully extracted at scale, could be used as fire retardants

The concept of treating materials to reduce their flammability has been around for centuries. Their use massively increased throughout the 20th century, along with the mass production of plastics and other polymers. This is because synthetic polymers produce hotter flames and burn faster than natural materials like wood. ‘These are really flammable materials that produce a lot of toxic smoke,’ says Svetlana.

Everyday items containing fire retardant chemicals include mattresses, curtains, sofas, clothes, TV sets, and white goods, as well as mobile phones, laptops and other gadgets powered by lithium-ion batteries. They are also present in the fabric of buildings, including in window frames, doors, loft insulation and the insulating facades on high-rise buildings.

Safer solutions

Such extensive use of fire retardants is causing concern in some scientific communities due to increasing evidence that some of these chemicals, when they leach out of the materials, are harmful to human health and the environment. The early fire retardants for plastics contained chlorine, bromine and antimony, which give off carcinogenic gases during combustion. ‘Everyone is moving to halogen-free and antimony-free fire retardants,’ says Svetlana.

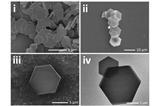

Among the new classes of fire retardants are inorganic compounds, such as aluminium trihydroxide, ammonium phosphates and organic compounds, which often contain phosphorus. There is also a drive towards finding sustainable fire retardants. ‘The future of fire retardant chemistry will be seeking alternatives from nature or waste products which we’d normally throw away,’ says Svetlana. Shells from eggs and seafood both contain molecules that, if they could be successfully extracted at scale, could be used as fire retardants.

More resources

- Grab your learners’ attention with this demonstration showing the danger of using water to extinguish a chip pan fire.

- Develop your students’ ability to successfully plan and carry out practicals with these resources and ideas.

- Show your students how a patent attorney works with new inventions in chemistry.

- Boost your learners’ problem-solving skills with activities from our In search of solutions collection.

- Discuss the impact of carbon emissions from incinerating waste plastic on the climate emergency with 14–16 learners.

More resources

- Grab your learners’ attention with this demonstration showing the danger of using water to extinguish a chip pan fire: rsc.li/47DysHD

- Develop your students’ ability to successfully plan and carry out practicals with these ideas: rsc.li/45fnIxx

- Show your pupils a video of how a patent attorney works with new inventions in chemistry: rsc.li/44hK68a

- Boost your learners’ problem-solving skills with activities from our In search of solutions collection: rsc.li/3OAdocu

Some scientists want to do more than just change the types of chemicals used as fire retardants – they want to significantly reduce how much these types of chemicals are used overall. This movement is driven by evidence that fire retardants can make it more likely that people will die in fires. ‘Flame retardants quench flames, they stop the reaction halfway through and therefore you get a lot more products of incomplete combustion,’ says Richard. ‘The main two of those products, carbon monoxide and hydrogen cyanide, are both asphyxiants that stop your body being able to use oxygen and therefore leave you unable to escape the fire.’

While the future of fire retardants is yet to be decided, other types of chemicals will, without a doubt, continue to play a vital role in keeping the world’s population – and especially firefighters – safe from fire.

Article by Nina Notman, freelance science writer and editor. Resource by head of science Catherine Smith and senior science technician Sandrine Bouchelkia

No comments yet