Nina Notman investigates efforts to reduce the environmental impact of our clothes throughout their life cycle, and what we as consumers can do to help

Fashion is a booming business. In the UK, we purchased 1,130,000 tonnes of clothing in 2016, according to a Waste and Resources Action Programme (WRAP) report. Up almost 200,000 tonnes since 2012.

A dress or T-shirt for the same price as an Americano can seem irresistible, until you start considering the wider impact of such a pick-me-up purchase. In the UK, WRAP found that in 2016 the carbon footprint of all the clothes in use was 26.2 million tonnes of carbon dioxide. In 2012, it was 24 million tonnes.

In your class

This article provides an excellent opportunity to discuss with students the wider impact their day-to-day choices have on the environment and can be used to support learning on sustainable development and life-cycle assessments. The context of fast fashion is one the students can relate to and is an area in which they themselves can make small changes that will have a larger impact.

Carbon dioxide emissions are only part of the story. The water footprint of our in-use clothes is around 8 billion m3 each year, according to WRAP. Garments also generate vast amounts of waste at multiple stages of their life cycles. (Fashion also has a significant ethical impact which this article doesn’t delve into.)

The fashion industry is starting to act to reduce the environmental strain of its products. But initiatives are currently swimming against a tide of increasing fashion production. ‘We’re still losing ground in terms of making ecological gains,’ explains Lynda Grose, professor of sustainable fashion at California College of the Arts in San Francisco, US.

Growth of raw products

A cotton garment starts life as a cotton boll on a cotton plant. ‘The way that we grow cotton can have some significant negative environmental impacts,’ says Mark Sumner, lecturer in fashion and sustainability at the University of Leeds. How cotton is grown determines the size of that impact.

Cotton is grown in approximately 80 countries and farming methods vary significantly around the globe. ‘We have highly mechanised, highly automated, high tech cotton production in places like the US and Australia. At the other end of the scale, we have very low tech, subsistence farmers producing cotton. And then we have everything in between,’ Mark says.

Irrigation, fertilisers and pesticides remain popular tools for boosting the amount of cotton produced per plant. Rain-fed cotton and crops grown using beneficial insects to combat pests or planted alongside ‘decoy’ plants, which attract problem pests away from the crop, have a smaller environmental impact.

Cotton grown using more sustainable practices is gaining in popularity. Earlier this year, Marks and Spencer revealed that 100% of the cotton in its clothes is now sustainably sourced. Tesco and Sainsbury’s have also committed to using only so-called sustainable cotton by 2020. All three retailers are members of the Better Cotton Initiative, a programme that provides training on more sustainable farming practices to more than two million cotton farmers in 21 countries.

Garment production

Once harvested, cotton bolls are converted via a number of production processes into garments. The first three – ginning, spinning and knitting or weaving – have a fairly low environmental impact mostly associated with energy use. ‘Ginning is separating the cotton fibre from the cotton seed,’ explains Mark. ‘It is quite low tech and normally done close to the farm. That cotton lint is then compacted into cotton bales and transported to a spinning mill.’ At the mill, the tangled mixture of cotton fibres is combed to align the fibres and then twisted together to form a yarn. The yarn is then either knitted or woven into fabric.

Scouring, bleaching, colouration and addition of functional finishes come next. All these processes can use a lot of energy, water and industrial chemicals. ‘The dyeing and finishing area is a real hotspot for environmental impact improvements,’ explains Mark. ‘Lots of work has already been done to develop new technology to minimise water, energy and chemical use,’ he adds.

Lynda explains that alternative cotton dying methods already in use include cold pad batch dying, that operates at room temperature and uses less water, and foam technologies, where the colour is applied to the fabric using a foam rather than water. Supercritical carbon dioxide is also being explored as a transport medium for dyeing cotton.

Download this

Worksheet, for age range 14–16

In this DART (Directed Activity Related to Text) students use the information provided in the article to carry out a life-cycle assessment of an item of cotton clothing, before reflecting on what they can do as individuals to reduce the impact of their clothing choices. Analysis through the use of the DART will help improve the students’ comprehension of the text and develop their critical reading skills.

After the dye has been applied, the fabric is washed to remove any loose dyestuff. Additional functional finishes are also added at this stage. ‘These range from a softener to high-performance finishes like a fire retardant or a waterproof coating,’ says Mark.

Next, fabric is cut and then sewn into a garment. ‘The environmental impact of this stage is low compared to what you’re seeing in other parts of the supply chain,’ he says. (It’s the ethical impacts that are critical here.)

Perhaps surprisingly, the environmental impact of the container shipping that transports the finished garment from the factory to the UK is also small. ‘It’s a myth associated with the textile industry that there is a large carbon footprint associated with shipping clothing from China to the UK,’ he says. The retail process also has quite a low environmental impact compared to other stages in a garment’s life cycle, although, notes Lynda, the warehousing and logistics of restocking shelves does add to the overall carbon footprint of a garment. Unsold goods also create a lot of waste.

Consumer impact

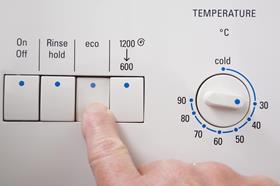

‘The next biggest impact is what the consumer does with the garment through its useful life,’ Mark explains. Washing, drying and to a smaller extent, ironing can have a significant environmental impact in terms of water, energy and chemical use. Small behaviour changes here can make a big difference.

‘Activators within washing powder have been modified to allow low temperature washing and there’s been a big push to get consumers to wash at lower temperatures,’ he says.

We should also revert to washing our clothes less often. The convenience of modern washing machines means ‘we wash our clothes more than we’ve ever done before’, Mark explains. ‘We’re not washing clothes because they need washing; we’re washing clothes just because we’ve worn them.’ Lynda concurs: ‘one of the smartest design concepts I’ve seen to change washing behaviours by the wearer, was a campaign stating “dirty is the new black”.’ We should also line dry.

What we do with garments at the end of their useful life also needs rethinking. Firstly, consider fixing, refashioning or upcycling them. Then, ask whether the item has really reached the end of its life or just the end of its life with you. ‘Studies show that garments are thrown away long before the end of their useful life,’ says Lynda. A garment’s life can be extended by gifting to friends and family, using resale platforms such as eBay or The RealReal, or donating to charity for resale.

‘The best thing that consumers can do is to keep their garments for longer, wear them often and buy second-hand garments because then the resources extracted to make the garment in the first place are used over and over again,’ Lynda explains.

Some brands are cottoning on to the economic benefits of enabling reuse of their garments. Lynda notes that San Francisco-based Yerdle provides the logistics and online platform for clothing brands like Eileen Fisher and Patagonia to support resale of their products. ‘Brands are realising that they can capture revenue from the second or third sale of the same item,’ she explains. ‘The fastest growing part of the fashion industry is now resale.’

Even once a garment is no longer useable, landfill is never a good option. Textile recycling plants sort donations manually, identifying garments for reuse and those that need recycling. The latter are then sorted by fabric type into appropriate recycling streams. Cotton garments, for example, can be shredded to make rags or turned into materials for insulation. A number of technical approaches such as Fourier-transform infrared spectroscopy and radio frequency identification tags are being explored to facilitate and speed up the future sorting process.

Blends can be a big challenge for recycling. ‘T-shirts nowadays that feel like cotton are often modal lycra, cotton rayon or cotton poly,’ Lynda explains. New technologies that can mechanically or chemically separate different fibres in fabrics – so they can be reused or recycled appropriately – are starting to come online, but aren’t yet in widespread use.

Other choices

But what about the eco credentials of different fabrics, is there a better choice than cotton? ‘It’s often a case of swings and roundabouts,’ Mark answers. Polyester, for example, is predominantly derived from oil but is highly durable, tends to resist staining and dries quickly.

Viscose – another popular fabric choice for consumers – does, however, get the eco thumbs down from both Mark and Lynda. Viscose fibres are regenerated cellulose, generally from managed forests. There are arguments for and against using wood for fabric production, but the bigger issue with viscose is its production stages. ‘The process of converting wood into a soft fine fibre is chemically, energy and water intensive,’ explains Mark. ‘Highly concentrated sulfuric acid is used as a major component of that process.’ Most bamboo fibres go through these same processing stages. (The exception is bamboo linen that is mechanically processed.) ‘When people talk about bamboo as a green fibre it gives me a twitch in my eye,’ he exclaims. ‘Me too,’ says Lynda.

In terms of carbon emissions during a garment’s life cycle, regardless of the fabric type, the end-user stage nearly matches that of its production process. Any changes we make – from washing less, at lower temperatures, to line drying – will have a huge impact for the better. Extending garment lifetimes by wearing them for longer, making improved end-of-use choices and buying second hand are also critical.

And for the items we do buy new, Mark and Lynda recommend becoming an ethical consumer. ‘If you find a brand that you believe is doing the right thing, you can act in a positive way and buy from them and boycott brands that are not doing the right thing,’ says Mark. ‘That way you can help drive the industry to change.’ ‘Buying second hand will also influence companies to produce less to begin with,’ adds Lynda.

Download this …

Worksheet, for age range 14-16

In this DART (Directed Activity Related to Text) students use the information provided in the article to carry out a life-cycle assessment of an item of cotton clothing, before reflecting on what they can do as individuals to reduce the impact of their clothing choices. Analysis through the use of the DART will help improve the students’ comprehension of the text and develop their critical reading skills.

- Download the activity and a PDF of this article from the EiC website: rsc.li/2p5KZ6o

More resources

- Explore sustainability in other areas of chemistry through these two recent EiC articles and the attached resources: What a waste! and How will we save our endangered elements?

- Students can experience the processes required for the colouration of cloth by preparing a sample of an azo dye and using it to dye a small piece of cotton in this practical activity. This can be extended by considering the environmental impact of the process.

- The Valuing our clothes report from WRAP makes for interesting reading on the environmental impact of the UK clothing industry. Students can also research some of the many campaigns around the environmental impact of our clothes, for example I prefer 30, Love your clothes and Dirty fashion.

- Using waste products to provide sustainable alternatives is one way scientists are trying to lower the environmental impact of manufacturing processes. Watch this video to find out more about how Raquel uses pineapple leaves to develop a sustainable fabric.

More resources

- Explore sustainability in other areas of chemistry through these two recent EiC articles and the attached resources: What a waste! and How will we save our endangered elements?

- Students can experience the processes required for the colouration of cloth by preparing a sample of an azo dye and using it to dye a small piece of cotton in this practical activity: rsc.li/33gJCjC This can be extended by considering the environmental impact of the process.

- The Valuing our clothes report from WRAP makes for interesting reading on the environmental impact of the UK clothing industry: bit.ly/2Mrvduk Students can also research some of the many campaigns around the environmental impact of our clothes, for example I prefer 30 (prefer30.eu/en), Love your clothes (loveyourclothes.org.uk) and Dirty fashion (bit.ly/2oifohA).

No comments yet