Watch the video and download technician notes from the Education in Chemistry website: rsc.li/2IoVGZG

The chemiluminescence of luminol is a fascinating way to demonstrate that energy changes in reactions don’t always involve the release or absorption of heat. But while the glow is beautiful and impressive, it can be brief and students often ask how other colours are made.

Luminol’s blue colour can be modified to more of a yellowy green by masking with fluorescein, but commercial glow sticks involve the generation of intermediates that do not themselves give off visible light but rather pass energy to dyes or ‘sensitisers’. These reactions also lend themselves to discussions or investigations of kinetics.

However, glow stick reactions often involve expensive dyes and the use of solvents that are either unlikely to be found in a typical school store (diethyl phthalate), or are unsuitable for use in school (dichloromethane). In this column, I’ll focus on a glow stick reaction that represents value, simplicity and safety.1

However, glow stick reactions often involve expensive dyes and the use of solvents that are either unlikely to be found in a typical school store (diethyl phthalate), or are unsuitable for use in school (dichloromethane). In this column, I’ll focus on a glow stick reaction that represents value, simplicity and safety.

Preparation of the chemiluminescent compound, bis(2,4,6-trichlorophenyl) oxalate (TCPO)

There are a variety of diphenylester compounds that can produce the desired results. TCPO is chosen for its favourable stability once synthesised, as well as the brightness and duration of the glow produced. The compound is prohibitively expensive to purchase but can be simply synthesised by a teacher or technician ahead of time – this could also be undertaken by reliable sixth-formers under close supervision in a science club.

The acid chloride reacts far faster than the carboxylic acid equivalent, and the removal of the evolved hydrogen chloride by the basic triethylamine helps to drive the reaction further towards completion with expected yields around 65%.2

The acid chloride reacts far faster than the carboxylic acid equivalent, and the removal of the evolved hydrogen chloride by the basic triethylamine helps to drive the reaction further towards completion with expected yields around 65%.

Kit

- 4.7 g 2,4,6-trichlorophenol (TCP) (irritant, harmful if swallowed, dangerous for the environment, suspected carcinogen)

- 40 cm3 acetone (flammable, irritant)

- 3.5 cm3 triethylamine (flammable, harmful if swallowed, toxic by skin contact)

- 1.5 cm3 oxalyl chloride (corrosive, respiratory irritant, contact with water releases flammable gases)

- 100 cm3 round-bottomed flask

- Drying tube

- Large beaker and approx 200 g ice for an ice bath

- Suction filtration apparatus

- Magnetic stirrer and follower

Preparation

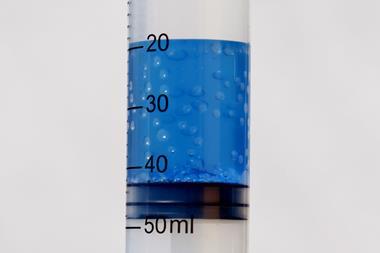

Work in a fume cupboard. Wear gloves and splash-proof goggles. Place a beaker to act as an ice bath on a magnetic stirrer and clamp a 100 cm3 round-bottomed flask within it. Add 4.7 g of TCP followed by 40 cm3 acetone. Start stirring the mixture and add 3.5 cm3 of triethylamine. Cool the mixture by adding ice and water to the beaker. Slowly add 1.5 cm3 of oxalyl chloride with time for cooling on each addition. Add one drop of triethylamine, place a drying tube on the flask and leave stirring for 20 minutes. The product will crystallise out and can be filtered, air-dried under suction and will remain stable in a sample vial for several months.

Demonstrating the glow stick reaction

The chemiluminescent reaction is initiated by the oxidation of the oxalate ester in the presence of hydrogen peroxide and catalysed by a base such as sodium acetate. The initial oxidation product is 1,2-dioxetanedione, which rapidly decomposes to electronically excited carbon dioxide. Alone this will not efficiently chemiluminesce but a fluorescent dye can capture energy from the CO2 efficiently and release this in the form of visible light.3

The chemiluminescent reaction is initiated by the oxidation of the oxalate ester in the presence of hydrogen peroxide and catalysed by a base such as sodium acetate. The initial oxidation product is 1,2-dioxetanedione, which rapidly decomposes to electronically excited carbon dioxide. Alone this will not efficiently chemiluminesce but a fluorescent dye can capture energy from the CO2 efficiently and release this in the form of visible light.

Kit

- Glass 20 cm3 sample vial with lid

- 5 cm3 ethyl acetate (flammable, irritant)

- 5 cm3 ethanol (flammable, harmful if swallowed)

- 2 cm3 10 vol hydrogen peroxide in ethanol (flammable)

- 0.1 g TCPO (irritant)

- 0.05 g sodium acetate

- 0.05 g rhodamine B (harmful if swallowed, causes serious eye damage, dangerous for the aquatic environment)

- Spatulas and wooden splints / microspatulas

In front of the class

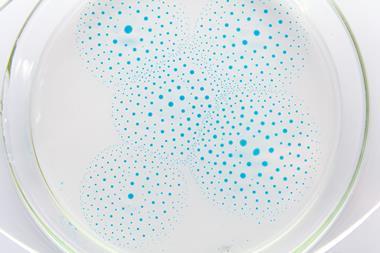

For the best effect work in a darkened room. Wear eye protection and gloves. Transfer approx ½ a spatula of TCPO to the sample vial (approx 0.1 g) and the tip of a splint / microspautula of the other two solids (approx 0.05 g). Add the ethyl acetate and ethanol then shake with the lid on to dissolve the dye and suspend the base. Finally add the hydrogen peroxide and shake the mixture one more time to initiate the reaction. The red glow will persist for several minutes.

Teaching goal

Numerous kinetic effects can be demonstrated here. First, it’s possible to show the catalytic behaviour of the base. Repeating the demonstration without this reagent will leave little to no visible glow, but on addition of the base, the glow will initiate – on close inspection the glow can be seen as the most dramatic around the suspended base powder particles. Further explorations showing the effect of increasing hydrogen peroxide concentration are very simple.

Other (potentially more costly) dyes are available to generate different and brighter colours – rhodamine B has been chosen for its relatively cheap price but rubrene gives a significantly stronger and longer-lasting orange glow. 9,10-diphenylanthracene also produces a brighter blue glow. Chlorophyll extracted from spinach leaves generates a red glow that can be discussed in the context of its green colour under visible light.

Temperature effects on the rate of reaction can be easily demonstrated by dipping the lidded sample vial in an ice bath and back into warm water – the glow will diminish and return accordingly.

Disposal

The mixture can be left to evaporate in a beaker at the back of a fume cupboard to leave a crystalline residue of 2,4,6-trichlorophenol and dye. The bulk of the solid material can be scraped into a container for collection by a registered waste contractor and any remaining material can be diluted and poured down a foul water drain.

Downloads

Technician notes - the glow stick reaction

Word, Size 53.26 kbTechnician notes - the glow stick reaction

PDF, Size 0.29 mb

References

1 R Nixon, School Science Review, 2011, 14

2 A G Mohan and N J Turro, J Chem Ed, 1974, 51, 528 (DOI: 10.1021/ed051p528)

3 G B Schuster, Acc Chem Res, 1979, 12, 366 (DOI: 10.1021/ar50142a003)

No comments yet