Try this class practical to make a soap or detergent using castor oil and either sodium hydroxide or sulfuric acid

Castor oil is used as a source of vegetable oils which, on reaction with warm concentrated alkali, form soaps. The vegetable oils in castor oil also contain hydroxy-groups (–OH) which will react readily with concentrated sulfuric acid, forming a long chain molecule with an ionic sulfonate group on the end. Such molecules behave as detergents.

In this experiment, students use sodium hydroxide or sulfuric acid to make their own soap or detergent. Only small quantities of reagents are required, reducing the risks associated with the use of such hazardous reagents.

Both procedures are suitable for reliable students, able to handle concentrated acids and alkalis responsibly, safely and with sufficient skill. The experiments will take about 45 minutes.

Equipment

Apparatus

- Eye protection (goggles) – safety spectacles are NOT suitable

- Test tubes, x4

- Boiling tubes, x3 (see note 1 below)

- Test tube rack

- Test tube holder

- Cork, to fit test tube

- Dropping pipette

- Measuring cylinders, 10 cm3, x2

- Beakers, 100 cm3, x2

- Beaker, 250 cm3

- Glass rod

- Spatula

- Bunsen burner

- Tripod and gauze

- Heat resistant mat

- Boiling water from an electric kettle (see note 2 below)

- Ice bath (optional) (see note 3)

- Filter flask, funnel, filter papers and pump (see note 4)

Apparatus notes

- A large (150 x 25 mm) test tube.

- At least two electric kettles, strategically situated around the laboratory, will be needed to allow students to fill their water-baths (250 cm3 beakers or larger, or a small metal waterbath). These should be preheated to boiling at the start of the lesson so that a rapid reheat is possible when students have to fill their water baths. It may be safer for students to take the electric kettles to their working places than to carry beakers of boiling water around the laboratory.

- An ice bath will help to speed up the precipitation of the soap produced. Again, two or more placed around the laboratory will probably be necessary.

- The solid soap needs to be filtered off using a pump. Four water-pumps set up around the laboratory, with filter flasks (100 cm3) and either small Buchner or Hirsch funnels, will allow the class to filter their products efficiently. Filter papers should be available to size for each funnel. If water pumps are not available, other types of suction pump can be used.

Chemicals

- Castor oil, about 5 cm3

- Ethanol (IDA, industrial denatured alcohol) (HIGHLY FLAMMABLE, HARMFUL), 5 cm3

- Sodium hydroxide solution, 5 M (CORROSIVE), 10 cm3

- Sodium chloride, 10 g

- Concentrated sulfuric acid (CORROSIVE), 2 cm3

- Purified water (distilled or deionised)

Health, safety and technical notes

- Read our standard health and safety guidance.

- Wear goggles at all times throughout these experiments. You are using 5 M sodium hydroxide and, in the second part, concentrated sulfuric acid, both very corrosive liquids. If you spill either of these on the skin, wash off at once in the sink with plenty of running water. Similarly, quickly mop up any spills on the bench with a damp cloth and then rinse it thoroughly.

- Castor oil – castor oil is the best oil for making soap in the school laboratory, but reasonable results can be obtained from olive oil and rapeseed oil. For making detergent by sulfonation, the hydroxy-group on the carbon chain is essential, and castor oil is necessary.

- Ethanol (IDA, industrial denatured alcohol), C2H5OH(l), (HIGHLY FLAMMABLE, HARMFUL) – see CLEAPSS Hazcard HC040A.

- Sodium hydroxide solution, NaOH(aq), (CORROSIVE) – see CLEAPSS Hazcard HC091a and CLEAPSS Recipe Book RB085.

- Sodium chloride, NaCl(s) – see CLEAPSS Hazcard HC047b.

- Concentrated sulfuric acid, H2SO4(l), (CORROSIVE) – see CLEAPSS Hazcard HC098a.

Procedure

Making soap

- Place castor oil (2 cm3) into a beaker (100 cm3) using a dropping pipette, followed by ethanol (5 cm3). Stir with a glass rod to mix.

- Add sodium hydroxide solution (10 cm3).

- Prepare a waterbath containing near-boiling water from an electric kettle so that you can safely lower the small beaker into it without spillage. A 250 cm3 beaker may be used as the waterbath. Do not use too much water, as the small beaker needs to be supported without risk of the water coming over the top.

- Stir the mixture in the beaker with a glass rod for 5 minutes. If the water bath cools too much, you may need to renew with fresh boiling water.

- Meanwhile in a boiling tube make a saturated solution of sodium chloride by shaking solid sodium chloride with 10 cm3 of water until no more will dissolve. Allow to settle.

- After 5 minutes, add the saturated sodium chloride solution to the small beaker and stir.

- Cool the mixture by changing to a cold water bath (or an ice bath if available).

- Soft, white lumps of the soap will gradually form in the mixture. Leave for a few minutes to improve the yield. During this time the soap may rise to the surface and form a soft crust on cooling.

- Using a pump, with a fresh filter paper damped down in the funnel, filter off the soap, breaking up the crust with a glass rod if necessary

- Allow the soap to drain on a paper towel – do not touch it with your fingers, as it may still contain sodium hydroxide.

- Use a spatula to transfer a little of the soap to a test tube, and add a few cm3 of purified water. Shake well! What happens? You have made a soap!

Making a detergent

- Add 4 cm3 of concentrated sulfuric acid to a boiling tube (your teacher may do this for you).

- Using the dropping pipette, add 2 cm3 of castor oil very carefully to the boiling tube, swirling gently to mix. Does the test tube become hot?

- Add 10 cm3 of cold water to a boiling tube (about 3–4 cm depth), then carefully pour the reaction mixture from the first tube into the water. The liquid may be very slow-flowing (viscous) and contain concentrated acid, so be careful and take your time over this.

- Stir to remove the excess of acid into the water and then decant (pour off) the water down the sink, leaving a pinkish-grey sludge. Wash the product again with two more portions of water.

- Use a spatula to transfer a small quantity of the product to a clean test tube. Add a few cm3 of water, and shake well. What happens? You have made a detergent.

Teaching notes

As these experiments involve the use of two very corrosive reagents, the reliability of the class in terms of both manipulative skills and behaviour is important. However, the quantities actually used are small, and risks can be minimised by advance preparation of reaction vessels with these reagents already measured out.

If you are uncertain about the reliability of the class, the experiments may be performed as demonstrations, but should not be scaled up. The use of a flexicam or similar to project onto a screen may help with visibility of a demonstration.

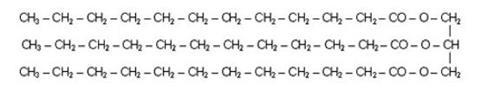

Castor oil is an example of a triglyceride, in which three long hydrocarbon chains (typically around 16 carbon atoms in length) are all linked through oxygen atoms to one 3-carbon chain at the end. The latter is derived from glycerol – hence the name triglyceride. A simple triglyceride structure looks like this:

For castor oil, the carbon chains are each 18 carbon atoms long. However, part way along each chain there is carbon–carbon double bond, with a hydroxy-group nearby. The double bond means that the chains do not pack well together, so this triglyceride is a liquid rather than a solid – a vegetable oil rather than a fat.

When boiled with sodium hydroxide, the glycerol end group is split off, and the long chains pair up with the sodium ions to form sodium ricinoleate, which is the soap.

The three hydroxy-groups on the carbon chains react with concentrated sulfuric acid to form a sulfonic acid group, –OSO2OH. These groups are water-soluble, but the hydrocarbon chains are not. It is this conflicting pair of properties that makes such substances good detergents, with the hydrocarbon chains mixing with greasy dirt and the sulfonic acid groups dissolving in water.

The detergent formed from castor oil is called Turkey Red oil. This was the first synthetic detergent to be made, and is still used in some bath oils.

Real-world context

Introduce or close this activity using this video job profile of Sharlotte, who makes environmentally friendly beauty products.

Further information

Wikipedia provides summaries and background information about key topics, including:

- The chemical structure of castor oil and its uses in soaps and detergents

- Triglycerides

- Soap and soap making

Unfortunately most websites concerned with making soaps and detergents begin with a basic soap or detergent, and simply add the extras – perfumes, colours and the like.

Additional information

This is a resource from the Practical Chemistry project, developed by the Nuffield Foundation and the Royal Society of Chemistry.

Practical Chemistry activities accompany Practical Physics and Practical Biology.

© Nuffield Foundation and the Royal Society of Chemistry

1 Reader's comment